Doc Holliday

WKR

- Joined

- Jun 15, 2016

- Messages

- 2,830

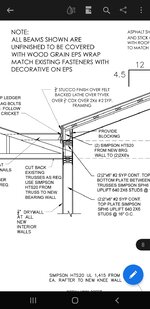

We are in the process of getting a permit for a renovation, and one of the finishes we need to go ahead and get on order are foam wraps for the new ceiling rafters, LVL beams, and collar ties. Basically it gives the look of rustic rough hewn timber. The guy who drew up our design made it sound like this is a readily available product, but we cannot find anyone around who has it in stock. Our GC is on the hunt, but has asked me to see what I can find as well. I have been on Google and found a few places (one in CA, one in NC, one in FL) that may or may not make what we need, but wanted to check with the brain trust here in case there are some recommendations. In looking at the "What do you do for a living?" thread, it seems many Roksliders are in the trades, so am hoping some folks on here might know of a source they can recommend who would work directly with the consumer/GC.

Thanks in advance

Thanks in advance