Something isn't jiving with these measurements to me, you got .009-.010" growth by seating a bullet?Outside diameter of the loaded shells that did not chamber with bullet still seated was .320 when measured with calipers and .322 when measured with a mic. A new brass out of the box measures .310 with calipers and .312 with a mic. After using the mandrel the new brass measures .312 with calipers and .313 with mic.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Solve this mystery

- Thread starter WTNUT

- Start date

TaperPin

WKR

- Joined

- Jul 12, 2023

- Messages

- 5,625

I must have missed that part. LolThanks do not think that is it here. It is brand new built custom rifle only fired 8 times thus far.

Sent from my iPad using Tapatalk

You can always check how tight the neck is with machinist gauge pins. 7 mag is pretty common so the gunsmith probably has a number of reamers and might have confused a no turn neck with a slightly tighter neck, or your brass is just extra thick and interfering with a no turn neck dimension.

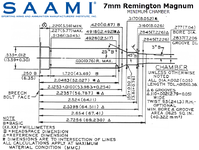

Saami shows a chamber neck of .316”-.318”

My “no turn neck” custom 7 mag chamber was .315”

Chambers for turned necks are probably in the .312” range

TaperPin

WKR

- Joined

- Jul 12, 2023

- Messages

- 5,625

.320“ is huge. LolOutside diameter of the loaded shells that did not chamber with bullet still seated was .320 when measured with calipers and .322 when measured with a mic. A new brass out of the box measures .310 with calipers and .312 with a mic. After using the mandrel the new brass measures .312 with calipers and .313 with mic.

Going to load a few later today and see if they chamber. Going to resize the brass that did not chamber after I pull powder and bullets.

Sent from my iPad using Tapatalk

wind gypsy

"DADDY"

- Joined

- Dec 30, 2014

- Messages

- 11,856

Outside diameter of the loaded shells that did not chamber with bullet still seated was .320 when measured with calipers and .322 when measured with a mic. A new brass out of the box measures .310 with calipers and .312 with a mic. After using the mandrel the new brass measures .312 with calipers and .313 with mic.

Going to load a few later today and see if they chamber. Going to resize the brass that did not chamber after I pull powder and bullets.

Sounds like nosler brass is too thick in the neck.

Doing the math on that would be .019" thickness, which would be the thickest I've ever seen. Something doesn't add up, running it over a mandrel only expanded it .001", and would equate to .009" interference fit. If that's true, I would assume that's why the shoulders are bulging. That's gotta be a ton of press force..Sounds like nosler brass is too thick in the neck.

What's the mandrel diameter?After using the mandrel the new brass measures .312 with calipers and .313 with mic.

rayporter

WKR

will a bullet drop easily into a fired case?

Many times the seating operation will cause this by having the seater die set too deep on the body. The seater stem is setting the length of the cartridge......BUT, the body of the die contacts the case mouth to perform a crimping process. If the crimping begins too early it will cause a shoulder buldge that is difficult to see.....but stops the case from going into the chamber.

You can smoke a case with a candle and try to load it or measure diameter right at the base of the shoulder to confirm.

You can smoke a case with a candle and try to load it or measure diameter right at the base of the shoulder to confirm.

A382DWDZQ

WKR

- Joined

- Dec 3, 2021

- Messages

- 828

what is the OD of the bullet? Is it possible you’ve got .308 instead of .284 somehow? Or too large of .284?

Well it too longer to get back to this than I expected. I used the same 15 cases and ran them through a full length sizing die. Then I used the same Wilson Mandrel and used it with plenty of case lube. This time the cases would chamber. Then I measured powder and seated the bullets. All chamber this time. The neck measures .314 this time.

Not real sure what happened. I think it was at least partially caused by not enough lube on the mandrel.

Not real sure what happened. I think it was at least partially caused by not enough lube on the mandrel.

This, I did this by accident. Thought my seating die was set correctly but wasn't. The range official that I know kept telling me that "you are hitting your rifling". Told him I wasn't and measured it in front of him. Wasn't until I got home and just so happened to look through my pics. I rememberd that my best friend wanted to try those 155 scenars that I was shooting in my 308. When I sent him the pic, I noticed it immediately.If the bullet seating force is too high, you can cause a case swell near the shoulder. I guess you could do the same with the mandrel. If the sizing die is squeezing the neck way down, and the mandrel is opening it way up, could be a problem. Lube it up!

I feel your humble pie pain.

I recently developed loads for a friend's new Howa 308. It had a very tight chamber and headspace at the extreme low end of the spec.

I had to adjust a sizing die I've been using for 30 years on multiple rifles. I had to screw it down to a strong cam - over height or empty cases wouldn't load. Plus, it had a sticky bolt. The bolt would raise just fine but darn if it would pull back! It didn't matter whether it was an empty case, or whether it had been fired! Don't know how many times I had to pull back while slamming the rifle butt down on the bench.

I got it shooting pretty good, but I am strictly not impressed.

I thought a blind pig could reload for any 308 until that happened.

Right where the shoulder meets the body you can see a small ring. Now the seating die didn't make the ring, The ring came from me trying to chamber it. What sucks was that I had loaded about 50 to go shoot. Had to pull all bullets, dump all powder, resize all brass, had wipe off all case lube and start over. Never once did I feel any resistance any different while seating the bullets. Juts forgot to reset the die after loading some 130ttsx.

.314 before or after seating a bullet?Well it too longer to get back to this than I expected. I used the same 15 cases and ran them through a full length sizing die. Then I used the same Wilson Mandrel and used it with plenty of case lube. This time the cases would chamber. Then I measured powder and seated the bullets. All chamber this time. The neck measures .314 this time.

I have never lubed a mandrel. Still curious what the mandrel diameter is, and why you had .009" interference based on the dimensions posted earlier, because I'm betting that's what bulged shoulders and wouldn't allow them to chamber.Not real sure what happened. I think it was at least partially caused by not enough lube on the mandrel.

I don’t recall the measurement of the Mandrel but I do recall it was about 3/1000 or so below .284. I will measure this evening. I do specifically recall that it was the first time I had used that new mandrel and I do recall it being “difficult” to insert or more so than I expected. You would have to also keep in mind that the mandrel could be sized right, but if the new brass is smaller in the inside diameter than normal it is also going to put more force on the case neck.

I understand that. If the mandrel is .003" below bullet diameter it should come out around .004" undersized after spring back.I don’t recall the measurement of the Mandrel but I do recall it was about 3/1000 or so below .284. I will measure this evening. I do specifically recall that it was the first time I had used that new mandrel and I do recall it being “difficult” to insert or more so than I expected. You would have to also keep in mind that the mandrel could be sized right, but if the new brass is smaller in the inside diameter than normal it is also going to put more force on the case neck.

This is what doesn't make sense, in your initial measurements "after using the mandrel the new brass measures .312 with calipers and .313 with mic". If the neck measured .322" with a mic after seating, that's .009" interference or neck tension. Unless you made a mistake in taking or posting your initial measurements, that would be a huge concern to me.Outside diameter of the loaded shells that did not chamber with bullet still seated was .320 when measured with calipers and .322 when measured with a mic. A new brass out of the box measures .310 with calipers and .312 with a mic. After using the mandrel the new brass measures .312 with calipers and .313 with mic.

Again, the neck measures .314 this time after running over a mandrel, or loaded round? I'm just trying to help you identify where or why you got .322", because that's quite a difference.Well it too longer to get back to this than I expected. I used the same 15 cases and ran them through a full length sizing die. Then I used the same Wilson Mandrel and used it with plenty of case lube. This time the cases would chamber. Then I measured powder and seated the bullets. All chamber this time. The neck measures .314 this time.

Similar threads

- Replies

- 12

- Views

- 338

- Replies

- 14

- Views

- 313

Featured Video

Latest Articles

- TT#64 Josh Boyd Elk Hunting Strategies for Every Season

- Aaron Davidson of Gunwerks

- TT#63 Dirk Durham’s Art of Elk Calling

- BIG Buck Stories with the Dirty Giants Podcast

- TT#62 Brian Barney Hunting Bulls without Calling

- Hoyt Alpha AX-2 SD Review

- Kuiu Kenai vs Outdoor Vitals Vario Hooded Jacket Review

- Hoyt RX-9 Ultra Review

- Hunting Vampire Bucks & Building an Optics Kit

- Darton Sequel ST2 35 Review