TradLife406

WKR

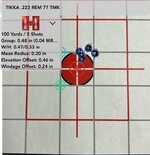

When I seat my 77 tmks with my el cheapo Hornady die for the 22 creed I get a ring mark on the jacket.

I tried the eldm and the standard stem. Is this normal? They still shoot amazing just wondering if there's something I'm doing wrong.

I saw somewhere a guy said it happens with compressed loads. Which mine definitely are. But it's the only powder and charge my gun likes.

Thanks fam

I tried the eldm and the standard stem. Is this normal? They still shoot amazing just wondering if there's something I'm doing wrong.

I saw somewhere a guy said it happens with compressed loads. Which mine definitely are. But it's the only powder and charge my gun likes.

Thanks fam