- Thread Starter

- #41

Cameron C

FNG

- Joined

- Aug 30, 2012

- Messages

- 76

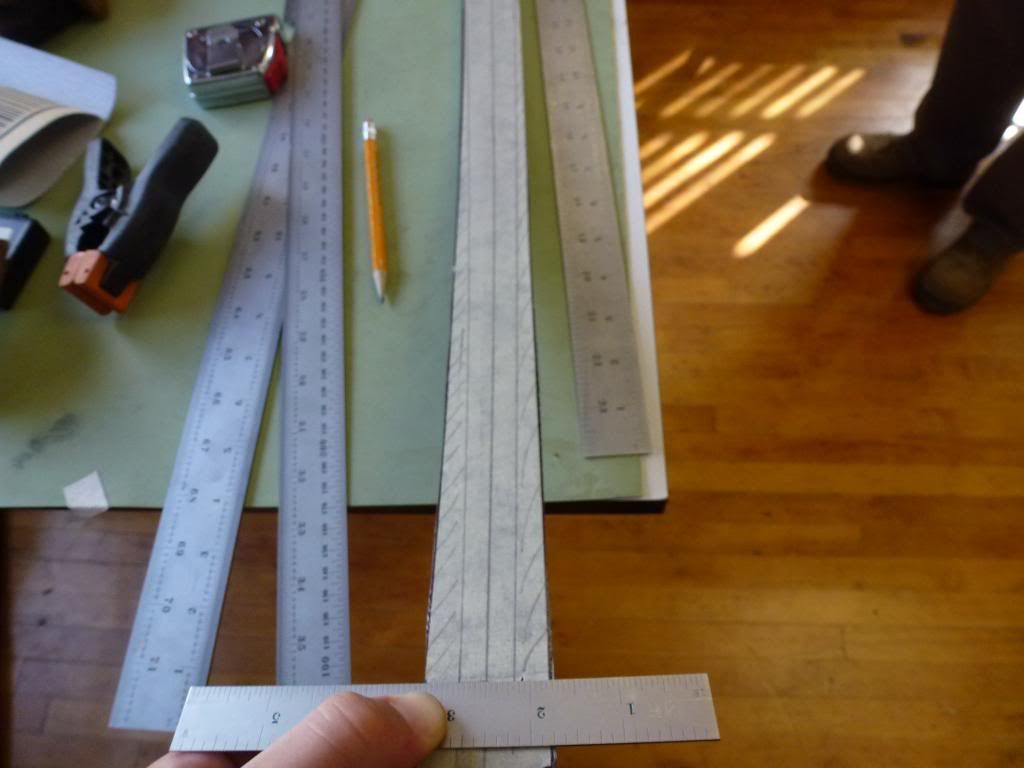

Thanks, it went well. It happened fast. Tomorrow I will take it out and cut the profile, and if time allows I'll sand the glue off the faces of the glass. The wrap will only keep the glue off the cauls, the clamps are already covered in glue, so I'll just have to give them a good scrape when I'm done.