Cameron C

FNG

- Joined

- Aug 30, 2012

Today I worked on getting the 0.001" tapers done. It was rough. I thought the way i did the 0.002" taper would work, but because of how thin the0.001" final dimensions were, it ended with some bad results. Some how the planer rollers pressed down on the lam and did some pretty big gouges. They were only about 0.007"-0.008" gouges, but I didn't want the tiller of the bow to be messed up, so my partner devised another way. Here is the messed up piece:

Here is the new plan of attack. Some pieces of 8020 just put together with double sided tape, and the desired taper shims between them. Then we just taped the maple lam to it and ran it through the table saw. It was brilliant!

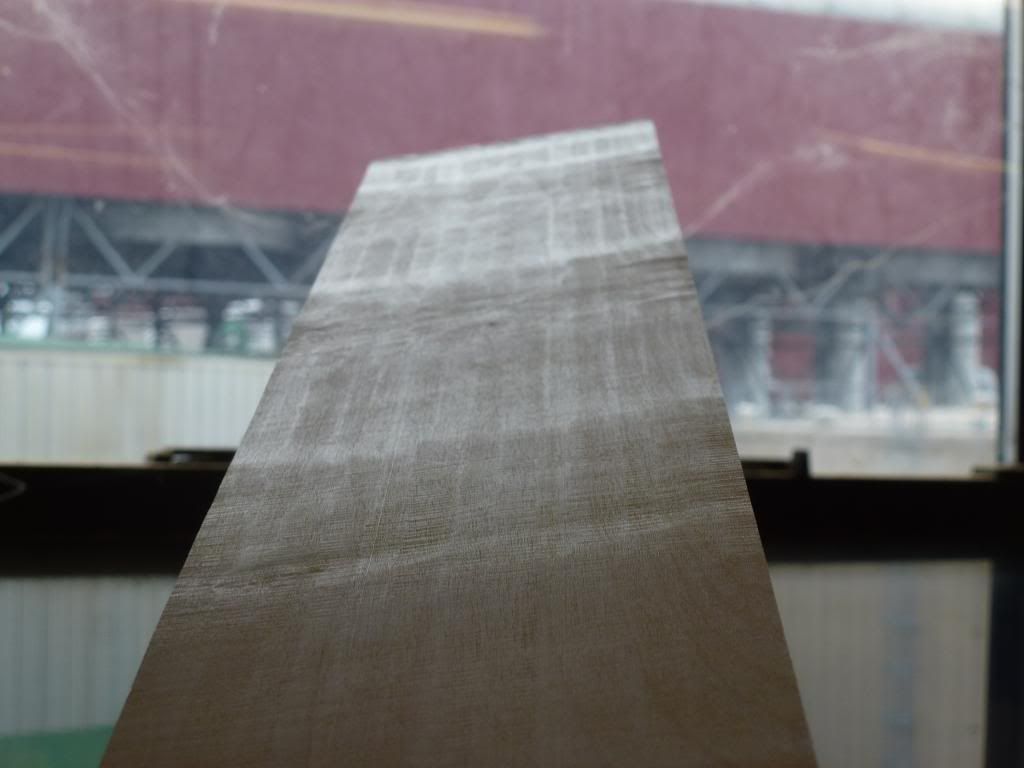

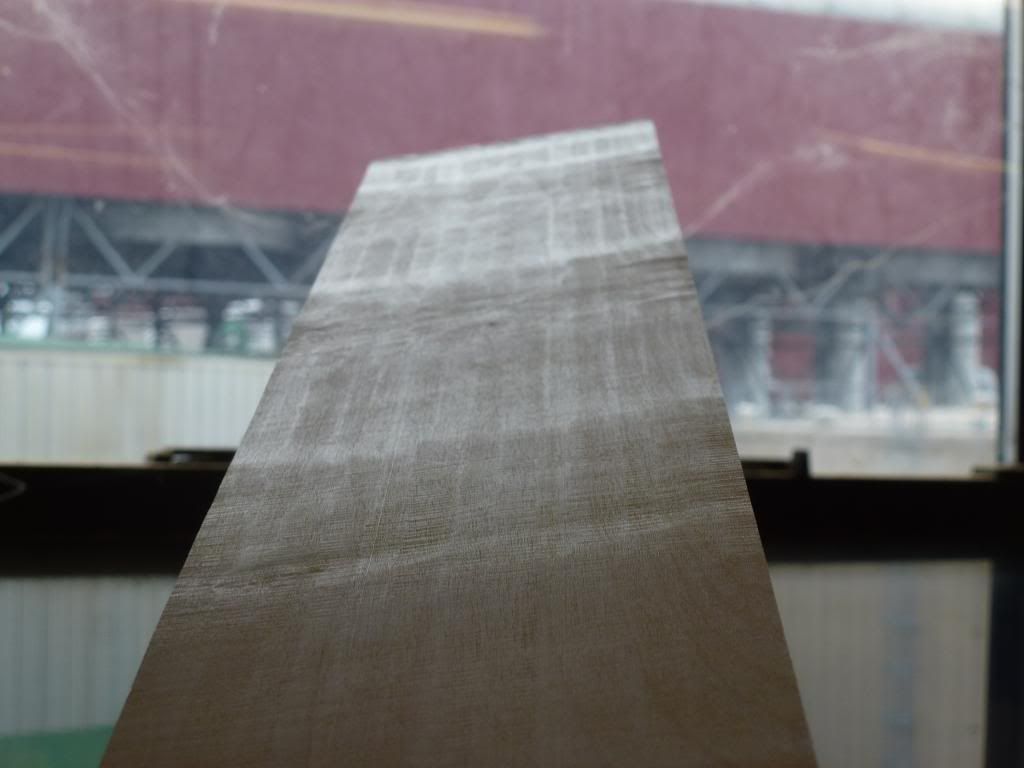

I will take no credit for this, my partner was the one running this thing through the table saw, and he hit the nail on the head. What a stud. Here's the 0.100" side:

Darn. Off by 0.0015". The bow probably won't work now... ha! That's an amazing cut, and here's the other side of the same piece. Shooting for 0.065"

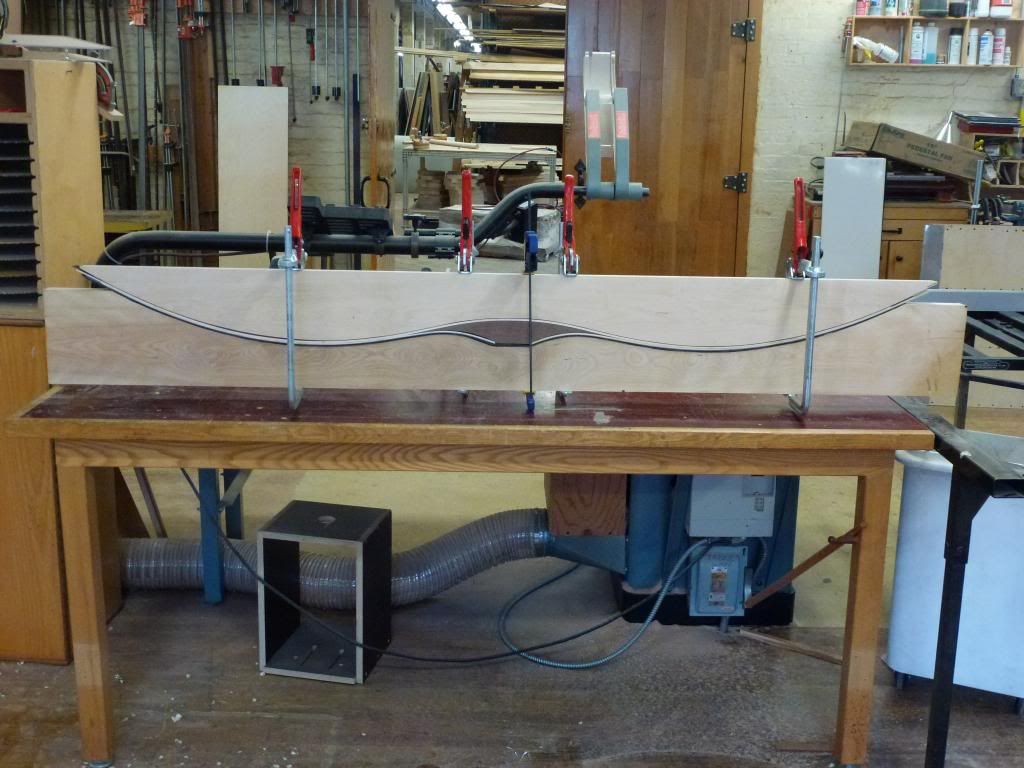

Now with the two belly tapers, We're all ready for glue up! I'm excited/ really content. This is going much faster and much better than I originally anticipated. I'm looking to have one glued up by tuesday at lunch. Going to do a dry run on monday and get everything prepped. Then hopefully glue and clamp it up on tuesday.

Here is the new plan of attack. Some pieces of 8020 just put together with double sided tape, and the desired taper shims between them. Then we just taped the maple lam to it and ran it through the table saw. It was brilliant!

I will take no credit for this, my partner was the one running this thing through the table saw, and he hit the nail on the head. What a stud. Here's the 0.100" side:

Darn. Off by 0.0015". The bow probably won't work now... ha! That's an amazing cut, and here's the other side of the same piece. Shooting for 0.065"

Now with the two belly tapers, We're all ready for glue up! I'm excited/ really content. This is going much faster and much better than I originally anticipated. I'm looking to have one glued up by tuesday at lunch. Going to do a dry run on monday and get everything prepped. Then hopefully glue and clamp it up on tuesday.