Just got my Winchester Model 70 featherlight back from ADCO. First time using them, based on a million recommendations I've read over the years and some look at their work first hand

Wasn't expecting this. Every other factory threaded barrel I have has a relief cut between the threads and the barrel that is minimum several thousandths smaller diameter than the threads. A couple random muzzle devices I have work bc they have relief cuts before the threads start. Ones that do not, obviously don't.

I'm pretty disappointed, but want to get some opinions before I contact them.

Below are pics of the threads, along with a random thread protector which obviously doesn't seat against the shoulder and a CAT 1/2-28 titanium HUB adapter on a Rugged Alaskan which does appear to seat properly.

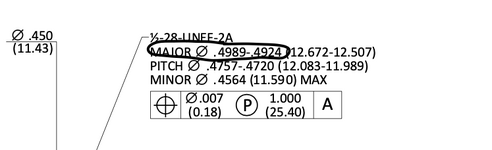

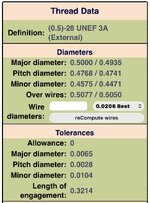

Major thread diameter on my cheap calipers is .493 (seems on the small side to me? Max spec for 1/2-28 is .498 if memory serves) The chamfer at the muzzle looks good and the threads themselves are nice and tight on everything I've put on. But where the relief cut should be is like 8/1000ths larger than the threads and will definitely prevent certain cans/devices being used

Am I tripping here?

EDIT: just went and looked closer at their website. Every example of a threaded barrel they have shows a beautiful, properly sized undercut.

I'm irritated.

Wasn't expecting this. Every other factory threaded barrel I have has a relief cut between the threads and the barrel that is minimum several thousandths smaller diameter than the threads. A couple random muzzle devices I have work bc they have relief cuts before the threads start. Ones that do not, obviously don't.

I'm pretty disappointed, but want to get some opinions before I contact them.

Below are pics of the threads, along with a random thread protector which obviously doesn't seat against the shoulder and a CAT 1/2-28 titanium HUB adapter on a Rugged Alaskan which does appear to seat properly.

Major thread diameter on my cheap calipers is .493 (seems on the small side to me? Max spec for 1/2-28 is .498 if memory serves) The chamfer at the muzzle looks good and the threads themselves are nice and tight on everything I've put on. But where the relief cut should be is like 8/1000ths larger than the threads and will definitely prevent certain cans/devices being used

Am I tripping here?

EDIT: just went and looked closer at their website. Every example of a threaded barrel they have shows a beautiful, properly sized undercut.

I'm irritated.