AkMtnRunner

WKR

- Joined

- Jul 24, 2016

- Messages

- 902

I am working up a load and would like to hear some thoughts on pressure. This is a 7 PRC, 160 LRX, Fed 215GM primer, Hodgdon 4831SC, new Peterson brass. The barrel is brand new by Patriot Valley Arms, 21" and 1:7" twist. I am just starting out the load work up, just trying to find where the pressure limit is.

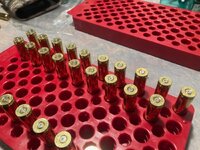

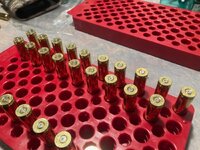

Below are a few photos of the primers. Back row - left is lowest charge going right, then front row rightmost is the highest charge. Disregard the front-most row partially out of frame. The lowest charge weight is 62.0 grains, all the way up to 68.0 grains. Barnes' starting load is 59.6 and max is 66.2. I should note that I am using a little longer COAL (3.38") than Barnes' (3.325"). I did load 6 rounds at Barnes' recommended COAL, which velocities were very similar to the same charge weights of the rounds with the longer COALs.

Despite exceeding book max charges, bolt lifts were easy all the way up to the highest charge weights, no extractor marks, and velocities were not impressive (~200 fps less than book expected with just 3" more barrel length).

To me, the primers do not look too flattened but I can certainly see a trend becoming more flat with higher charges. I understand a longer COAL can decrease pressure, so that was the reason why I tried some at Barnes' recommended COAL, but that turned out to not make any significant difference. I've measured the COAL for this bullet to engage the lands at 3.52" in my barrel.

What say ye? Safe to keep going up in charge or just accept this a slow barrel, perhaps due to excessive twist?

Below are a few photos of the primers. Back row - left is lowest charge going right, then front row rightmost is the highest charge. Disregard the front-most row partially out of frame. The lowest charge weight is 62.0 grains, all the way up to 68.0 grains. Barnes' starting load is 59.6 and max is 66.2. I should note that I am using a little longer COAL (3.38") than Barnes' (3.325"). I did load 6 rounds at Barnes' recommended COAL, which velocities were very similar to the same charge weights of the rounds with the longer COALs.

Despite exceeding book max charges, bolt lifts were easy all the way up to the highest charge weights, no extractor marks, and velocities were not impressive (~200 fps less than book expected with just 3" more barrel length).

To me, the primers do not look too flattened but I can certainly see a trend becoming more flat with higher charges. I understand a longer COAL can decrease pressure, so that was the reason why I tried some at Barnes' recommended COAL, but that turned out to not make any significant difference. I've measured the COAL for this bullet to engage the lands at 3.52" in my barrel.

What say ye? Safe to keep going up in charge or just accept this a slow barrel, perhaps due to excessive twist?