Is this common to have pressure quicker in fires brass compared to virgin.I’ve found lately that fired brass frequently builds pressure quicker than virgin even if the case is a little bigger.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pressure in a new tikka

- Thread starter T28w

- Start date

wind gypsy

"DADDY"

- Joined

- Dec 30, 2014

- Messages

- 11,855

Is this common to have pressure quicker in fires brass compared to virgin.

My experience is that fired brass with minimal resizing (i.e. larger internal case volume) will show slightly higher speed than virgin brass all else being the same. Only in one case do I recall it actually resulting in pressure signs so I can't say definitively that it has higher pressures but velocity and pressure are usually related.

The explanation I've seen for this is that virgin brass uses some of the energy expanding the case to fill the chamber compared to a minimally sized fired case where that energy goes into propelling the bullet.

Nope. Can’t remember what my coal is off the top of my head but I seated just deep enough to fit in the magazine.

Have you confirmed that that OAL isn’t jammed?

Sent from my iPad using Tapatalk

Yes. Reconfirmed actually yesterday with a diff bullet.Have you confirmed that that OAL isn’t jammed?

Sent from my iPad using Tapatalk

Do have an update for those that have helped. I really appreciate the input. It’s going to be kinda anti climatic though. I have been reading everything I could find on reading pressure signs and can accross an article that I will post here if that is not against forum rules. It talked about false swipes from a bur or a sharp area around ejector. It’s confirmed by load a shell, close bolt, unload and see if mark is still present. It was on mine. The article talks about it is more prevalent with softer brasses.

So for now I’m sticking with 62.5 until I get through the 100 pieces I have, almost there. Then I will go back up and see how it goes.

Shot it today and brother shot at 300 yards and grouping very nice. Plus we leave Wednesday for Colorado and I have stretched it out confirming velocity and drops and am content with the load for now.

So for now I’m sticking with 62.5 until I get through the 100 pieces I have, almost there. Then I will go back up and see how it goes.

Shot it today and brother shot at 300 yards and grouping very nice. Plus we leave Wednesday for Colorado and I have stretched it out confirming velocity and drops and am content with the load for now.

Lawnboi

WKR

Yea that is just ejector wear. Nothing to worry about.View attachment 335083View attachment 335083View attachment 335084

These just tumbled with some ss media trying it out. It was clean on the base. Chambered it and unloaded and u can clearly see the swipe mark from just chambering the round

Your chamber and cartridges need to be clean and dry. Sloppy lube esp. case lube can do that surely as you're reading this. Case lube a factory shell and pop one off. Then dry chamber &new case and try again. It will prove or disprove the idea. Solid copper bullets are longer and have more bore contact, and can raise pressure if that's what you're loading.Ok guys. Need some input now.

Went to range. Using Barnes recipe of min load of 62.4 and max over 69 of h4350. Barnes 168 ttsx. Cci mag primer 250, Norma brass never fired. Loaded up a ladder test.

New never fired tikka t3x 300 wsm.

Loaded a couple at 64 gr for sighters.

Had a very heavy bolt lift and what appears to be extractor mark. Shoot another and pretty much same result. So i stopped and dropped back to to lowest charge I loaded which was 63 even. Pretty much the same bolt lift, maybe slightly better. Went ahead and shot the 63.7 loads and then a 64 or two to end. If almost felt like it was getting a better bolt lift but still signs of a extractor swipe.

Chrono is measuring 2950 with 63 gr. And 3000 and just above with 63.7 and 64.0 gr.

Barnes recipe is 2847 with 62.4

And 3126 with 69.4.

I know my seating depth is slightly inconsistent but I’m very sure of my measurements to lands. Verified it 3 diff days and always getting within a couple thousands each time with a modified case (Norma from copper creek) and hornady lnl gauge.

Thoughts?

25165AB1-29F9-4449-8092-1FE50FA8441B.jpeg DB4AE229-EDBB-4F0F-B550-243A313556AA.jpeg

This concept is easy to overthink but case density has little to no affect on pressure, getting closer to the lands and decreasing the space of alleviation does. This is why factory rifles have tons of freebore and SAAMI ammo seems so short, and there are also tons of published compressed loads at a spec COAL.Also, since case capacity affects pressure, if this brass grew 8 thousandths and I bump it 2 back, has the case capacity increased of any significance to create less pressure?

It looks like you've figured out your issue, but undersized brass can also give false pressure signs from slapping the bolt face during expansion.

il_cop

Lil-Rokslider

Reviving as I'm looking at the same issue and would appreciate some thoughts.

Brand new Tikka - 30 rnds down it now

6.5 cm

Rl16

143 eldx

New Peterson brass

Full length sized

Expander mandrel at .262

All lube cleaned

I started at max, saw pressure in one shot, no problem

Dropped to 41gr

.050 jump

Seeing ejector marks and some swiping. No other pressure signs. Is pressure this or ejector wear as stated above?

I have no problem dropping the charge, not looking for speed, just accuracy, but I'd prefer not to waste components if the is a sharp/strong ejector or somethng other than pressure.

Brand new Tikka - 30 rnds down it now

6.5 cm

Rl16

143 eldx

New Peterson brass

Full length sized

Expander mandrel at .262

All lube cleaned

I started at max, saw pressure in one shot, no problem

Dropped to 41gr

.050 jump

Seeing ejector marks and some swiping. No other pressure signs. Is pressure this or ejector wear as stated above?

I have no problem dropping the charge, not looking for speed, just accuracy, but I'd prefer not to waste components if the is a sharp/strong ejector or somethng other than pressure.

Attachments

wind gypsy

"DADDY"

- Joined

- Dec 30, 2014

- Messages

- 11,855

Peterson brass has less internal volume than what is used in almost all load manuals thus it builds pressure faster. I've not shot peterson much so cant say much about the ejector stamp, i wouldn't fret if it was norma/hornady with that but with some others I'd think it may mean something.

If your velocities aren't indicating pressure and you dont have sticky bolt lift, I'd rock on personally.

If your velocities aren't indicating pressure and you dont have sticky bolt lift, I'd rock on personally.

il_cop

Lil-Rokslider

@wind gypsy thank you

I developed this load in a previous 6.5 (41 gr rl16, 143 eldx) at 2710 fps with lapus brass. Any idea how Peterson volume and thickness compares?

Sounds like I need to break out the chrono...

I developed this load in a previous 6.5 (41 gr rl16, 143 eldx) at 2710 fps with lapus brass. Any idea how Peterson volume and thickness compares?

Sounds like I need to break out the chrono...

wind gypsy

"DADDY"

- Joined

- Dec 30, 2014

- Messages

- 11,855

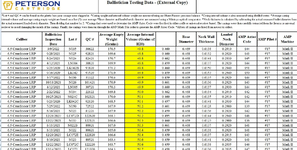

Case capacity varies by lot. There have been a number of threads here and elsewhere with people getting pressure signs on creedmoor loads in peterson brass prior to hitting "book max" charges though. Pic below is stolen from a thread about creedmoor case capacity elsewhere - very nice of Peterson to publish such info!@wind gypsy thank you

I developed this load in a previous 6.5 (41 gr rl16, 143 eldx) at 2710 fps with lapus brass. Any idea how Peterson volume and thickness compares?

Sounds like I need to break out the chrono...

il_cop

Lil-Rokslider

Excellent. Ty

Similar threads

- Replies

- 23

- Views

- 944

- Replies

- 11

- Views

- 6K

Latest posts

-

-

PSA: Initial ascent bags and accessories made in Taiwan

- Latest: StickSlingers

-

-

-

Featured Video

Latest Articles

- TT#64 Josh Boyd Elk Hunting Strategies for Every Season

- Aaron Davidson of Gunwerks

- TT#63 Dirk Durham’s Art of Elk Calling

- BIG Buck Stories with the Dirty Giants Podcast

- TT#62 Brian Barney Hunting Bulls without Calling

- Hoyt Alpha AX-2 SD Review

- Kuiu Kenai vs Outdoor Vitals Vario Hooded Jacket Review

- Hoyt RX-9 Ultra Review

- Hunting Vampire Bucks & Building an Optics Kit

- Darton Sequel ST2 35 Review