Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Not my Tikka! Fired engaging safety

- Thread starter Tahoe1305

- Start date

I had never heard of this issue either, which is surprising given the sheer volume of Tikka info and shooters here.Yes. I don’t think I had a full 133 in lbs.

Like many I remove the OEM springs to put in chassis and whatnot. I’ve always used the “just get it as tight as you can” method. Wasn’t enough I guess in my case. Torque wrench clearly applied more torque in my case.

I wasn’t aware this was a “common” issue. I’m pretty active on the forum and have been for some time (8 years I’m guessing) but first I’ve seen anyway.

If nothing else it’s another thread that may help some folks in similar position. I know for a fact some folks are going to check tension on em.

Well most people buy a firearm and leave it alone. Sure, on this site there may be a larger % of owners who modify, but in the grande scheme, most people leave em alone. I think a % of people within this niche forum doesn’t equate to most owners. Shit, I bet most owners aren’t on this site and even more not even on firearms forums or hunting forums at all.

At least we know

At least we know

Attachments

Ram94

WKR

- Joined

- Jul 24, 2019

- Messages

- 696

Looks like Fix-It-Sticks only has 100 and 140 in/lbs. Would the 140 be too much? This thread has me wanting to verify my own shit.

No, 140 should be just fine. Still under the rating for the screw. Even if it is off by 10% on the high side, you will still not exceed the screws rating.Looks like Fix-It-Sticks only has 100 and 140 in/lbs. Would the 140 be too much? This thread has me wanting to verify my own shit.

Looks like Fix-It-Sticks only has 100 and 140 in/lbs. Would the 140 be too much? This thread has me wanting to verify my own shit.

20-20 inch pounds for $18.

Ram94

WKR

- Joined

- Jul 24, 2019

- Messages

- 696

Unfortunately Harbour Freight doesn’t ship to Canada but I was able to find one on Amazon. Thanks guys!

20-20 inch pounds for $18.

Thread locker isn't going to hurt anything. I will probably switch all mine over from blue to red and just use a heat gun if I need to take the trigger off.Is anyone using or should you use some sort of thread locker

I feel this is a significant enough concern to warrant overkill (low probability, high risk). Or, as I was told once, when a big brown is trying to eat you, there is no such thing as overkill and fell free to keep shooting once it is on the ground.

JohnJohnson

WKR

- Joined

- Jun 12, 2019

- Messages

- 2,086

Something I wasn't aware of until recently was spraying the screws with Loctite Klean n' Prime before applying the Loctite to cut down the chances it will fail to cure.

SupressYourself

FNG

- Joined

- Jul 29, 2020

- Messages

- 20

I know this isn't really the point of this thread, but since it came up... on the factory mag spring thing... is it a "no longer necessary, but doesn't hurt anything" situation if you leave it in when switching to a chassis?

I'm a bit new to Tikkas, and I left mine alone when I dropped it in a XLR Element. Seems to function without issue.

I'm a bit new to Tikkas, and I left mine alone when I dropped it in a XLR Element. Seems to function without issue.

wind gypsy

"DADDY"

- Joined

- Dec 30, 2014

- Messages

- 13,173

I know this isn't really the point of this thread, but since it came up... on the factory mag spring thing... is it a "no longer necessary, but doesn't hurt anything" situation if you leave it in when switching to a chassis?

I'm a bit new to Tikkas, and I left mine alone when I dropped it in a XLR Element. Seems to function without issue.

I'm pretty sure the spring would get in the way on a KRG chassis. Surprised it works with an XLR?

dårlig jeger

Lil-Rokslider

- Joined

- Nov 23, 2025

- Messages

- 240

Krg bravo directions do indicate that you remove the spring for t3 install.

I went back through my tikkas to double check that my trigger screws were tight enough. I used 11 ftlbs, and wow, is that a lot more than I was putting them on with. I needed a c-clamp to hold the spring square.

My 223 had a light aftermarket spring in the trigger. It hadn't given me any trouble in a few thousand rounds, so I was going to leave it in there.... but once I tightened the retention bolt to 11, it would release the firing pin on bolt close. So I put a few more turns on the trigger adjustment screw and it would hold.

But, I knew that was asking for trouble, so I spent an hour digging out my factory spring and I reinstalled it. I'll miss how light the trigger was before. But now I can sleep at night knowing all my tikka trigger assemblies are tight as heck and all my springs are factory.

If you're on the fence about taking care of yours, I'd recommend just doing it.

I went back through my tikkas to double check that my trigger screws were tight enough. I used 11 ftlbs, and wow, is that a lot more than I was putting them on with. I needed a c-clamp to hold the spring square.

My 223 had a light aftermarket spring in the trigger. It hadn't given me any trouble in a few thousand rounds, so I was going to leave it in there.... but once I tightened the retention bolt to 11, it would release the firing pin on bolt close. So I put a few more turns on the trigger adjustment screw and it would hold.

But, I knew that was asking for trouble, so I spent an hour digging out my factory spring and I reinstalled it. I'll miss how light the trigger was before. But now I can sleep at night knowing all my tikka trigger assemblies are tight as heck and all my springs are factory.

If you're on the fence about taking care of yours, I'd recommend just doing it.

fwafwow

WKR

- Joined

- Apr 8, 2018

- Messages

- 6,269

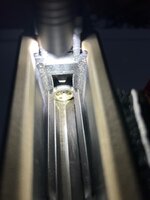

By "it" - do you mean "the allen bolt with the Red paint" in post #26?I got back and took a look first thing.

It was loose, just a bit. Enough for a small wiggle.

The T3x manual is not as specific as the Sako that Form posted. Am I missing/overlooking the similar torque specs?

I, for some reason, had 65 in lbs in my notes and must have been oblivious or taken that spec from a wrong source.BL: I don’t think I’ve been using the full 133 spec’d torque. And guessing those without a wrench or something other than a maxed out Allen key are getting it either. But I’ve been wrong before. Guessing I was closer to 80-90 in lbs using just the Allen wrench.

Thank you for the thread.Time to check the tikka family for similar.

It was a good lesson to learn and no one got hurt, so counting it as a win.

Appreciate the replies.

Guess I will order this, as my Borka also goes only to 70.

20-20 inch pounds for $18.

By it I meant the entire assembly and thus the only bolt holding it together (the one with the red paint). The bolt was still snug, but it needs to be tight to allow zero movement. And apparently tighter to not back out.By "it" - do you mean "the allen bolt with the Red paint" in post #26?

The T3x manual is not as specific as the Sako that Form posted. Am I missing/overlooking the similar torque specs?

I, for some reason, had 65 in lbs in my notes and must have been oblivious or taken that spec from a wrong source.

Thank you for the thread.

Guess I will order this, as my Borka also goes only to 70.

I haven’t seen that spec before either.

fwafwow

WKR

- Joined

- Apr 8, 2018

- Messages

- 6,269

Thanks. I am one to overlook a lot of things (just ask Mrs. fwafwow), but 133 in lbs is so out of the norm (beyond my tools), I must admit to being completely ignorant on this. I'm going to search to see how I missed it.By it I meant the entire assembly and thus the only bolt holding it together (the one with the red paint). The bolt was still snug, but it needs to be tight to allow zero movement. And apparently tighter to not back out.

I haven’t seen that spec before either.

EDIT - I took 65 in lbs from the Tikka slam fire thread - https://rokslide.com/forums/threads/tikka-slam-fire-psa.356257/, but now see others had posted 80 and TIGHT. I'm going to cross-post this thread with that one.

- Joined

- Oct 22, 2014

- Messages

- 14,668

I love leading horses to water and them refusing to drink, only to collapse later due to dehydration.

You're a glutton for punishment. The patience for people who don't trust you shows you could've been a great Kindergarten teacher in another life.I love leading horses to water and them refusing to drink, only to collapse later due to dehydration.

Similar threads

Featured Video

Latest Articles

- Banning Hunting Technology in Idaho?

- Best Gear of the year Rokslide staff edition 2025 Article

- Hunting Gear: Insights from Western Hunting Expo

- Black Diamond Alpine Start Insulated Hoody Review

- Tenacity Firearms with Andrew Whitney

- The Thrill of Moose Hunting with Henry Ferguson

- Final Rise Upland Hand Muff Review

- Kodiak Deer Hunt Round II

- Killing a Timber Giant

- Titanium Suppressor Shootout