I've been wracking my brain trying to figure out how I want to put together the upper frame sleeve while cutting down on bulk and weight for the assembly. It may not work out, but I've settled on milspec grosgrain ribbon, reinforced with 17337 over the tip of the stays. I could have used fabric, but then you have to deal with folding edges over and unnecessary seam bulk.

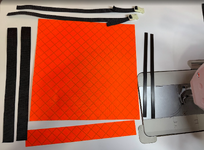

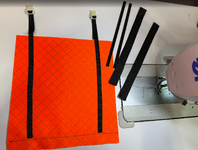

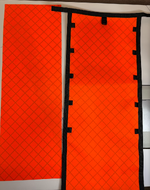

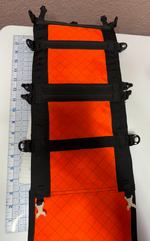

Here's my rushed weeknight, kids' bedtime fast approaching, attempt to mock something up. 1" orange ribbon used so you can see how I have things stitched and the rough order of assembly, but will be using black ribbon for both in the real thing so it doesn't look like crap.

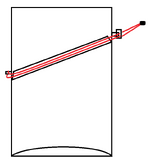

Two lengths of 1.5" grosgrain (real assembly will be one piece, looped over the top of the stay) create a sleeve for the aluminum stay, and sandwich a layer of Ecopak (sticking with the orange fabric). to close up the back between the stays. The 1" cross ribbon will create a loop (on the left in the pic) for plastic hardware, and wraps around and terminates on the back side. The horizontal cross ribbon will also capture a carbon fiber cross member.

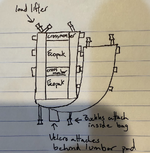

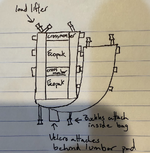

My drawing skills aren't much better than my Paint skills, but here's the concept for the upper frame assembly. Keep in mind, with no fixed vertical stays, this will roll up with the tent pole stays and stash inside the pack most of the time.

The rough order of operations will be (writing this down as much for myself as someone else who might want to attempt this):

- Sew small section of 17337 webbing reinforcement into inside of 1.5" ribbon at midway point of ribbon

- Sew load lifter and top buckle webbing at midway point of ribbon, opposite face of the ribbon to use the 17337 as backing

- Attach single layer Ecopak panel--length of half the 1.5" grosgrain--to the vertical grosgrain sections

- Insert and position any plastic hardware on 1" grosgrain.

- Stitch 1" grosgrain to front and back sides of 1.5 vertical grosgrain (front and back sides of the sleeve are still separate at this point).

- Fold the front and back sides of the 1.5" vertical grosgrain together. Before stitching the vertical seams that create the sleeve for the tubing, insert horizontal crossmembers under the 1" horizontal ribbon.

- Stitch the vertical seams for the 1.5" grosgrain, enclosing the horizontal crossmembers and creating the sleeve for the tent pole tubing.

- probably sew in bottom/outside section of cargo panel, attachment points for inside bag, and velcro during this step

- Bartack 1" grosgrain loops for reinforcement

I'll try to take pictures along the way so it's more clear than this mess ^. There's a good probability I've overlooked something glaringly obvious with these steps and I'll get to the end and realize I've sewn something shut that I shouldn't have or forgotten to add sewn in hardware. Or, maybe it's all okay, and the design simply fails, frame buckles under load when I first test it out.