You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is this ring on my jacket rifling?

- Thread starter Outdoorsman12b

- Start date

stanginthe11s

WKR

- Joined

- Jul 6, 2022

- Messages

- 571

ok, so I see that some are comparing the differences between jammed vs not jammed, to that I say that was never my intention with my original statement. however, since were here, I'd like to point out that the last words used in the first paragraph of what gypsy wrote are "and not at max pressures." realize, we have 0 data on the OP's load and the decision was to bump back.

now let's look at another ex., I have and do load long on some rounds, yes some are in the rifling. it is common practice, and it allows me to get a little more powder in that case. if I took that same round which is safe (borderline) with its increased powder and just bumped it back .050 guess what would happen.

point being, jammed does not mean unsafe and seating deeper does not mean unsafe, either can and does work. as a new reloader its always important to have all the info, whether it pertains to that specific scenario or not. and as someone helping, its equally important if not more so to have all the relevant data.

now let's look at another ex., I have and do load long on some rounds, yes some are in the rifling. it is common practice, and it allows me to get a little more powder in that case. if I took that same round which is safe (borderline) with its increased powder and just bumped it back .050 guess what would happen.

point being, jammed does not mean unsafe and seating deeper does not mean unsafe, either can and does work. as a new reloader its always important to have all the info, whether it pertains to that specific scenario or not. and as someone helping, its equally important if not more so to have all the relevant data.

BBob

WKR

The OP's picture clearly "sorta" shows a radial mark on the bullet, are you suggesting that a scratch along the axis of the bullet from it sliding against a sharp surface while chambering a round is the same thing ?? I don't think we know enough about his reloading discipline to tell him to "don't worry, just shoot it.Fat bullet or tight throat or sharp edge at entrance of throat or any combination of the above. Scratches bullet on the way in at beginning of throat. Common and not much to worry about. Shoot it.

View attachment 493888

That's the way i see it from where i stand ............

Why are you guessing? Measure where your lands start and seat back from there. Reloading 101.Yup I loaded to mag length. I tried chambering a factory loaded round and did not get the ring so thinking this must be “jam” I’ll try bumping back another 50 thou.

35WhelenAI

WKR

- Joined

- Nov 20, 2021

- Messages

- 1,873

Factory round with the same bullet?Yup I loaded to mag length. I tried chambering a factory loaded round and did not get the ring so thinking this must be “jam” I’ll try bumping back another 50 thou.

- Thread Starter

- #27

OP

Outdoorsman12b

WKR

- Joined

- Sep 24, 2018

- Messages

- 552

Why are you guessing? Measure where your lands start and seat back from there.

This makes the most sense as I cannot see any rifling marks leading up to the “ring” when sharpied.Fat bullet or tight throat or sharp edge at entrance of throat or any combination of the above. Scratches bullet on the way in at beginning of throat. Common and not much to worry about. Shoot it.

View attachment 493888

35WhelenAI

WKR

- Joined

- Nov 20, 2021

- Messages

- 1,873

Again, is that a factory load with the same bullet you are loading?Yup I loaded to mag length. I tried chambering a factory loaded round and did not get the ring so thinking this must be “jam” I’ll try bumping back another 50 thou.

- Thread Starter

- #29

OP

Outdoorsman12b

WKR

- Joined

- Sep 24, 2018

- Messages

- 552

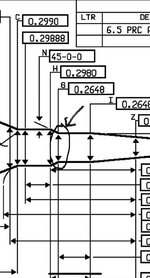

For those of you still following along… To help put in context the method I use to find lands is to jam by seating a bullet long then letting the bolt seat the bullet the rest of the way. Tonight I did this for the the new rifle (tikka T3X) the ring is appearing on 143 eldx. (Method #3 detailed here

)

Using Hornady bullet comparator before “jam” CBTO measures 2.432.

Pic of bullet sharpied up. Note the ring from bullet comparator.

Now jam measurement after seating in chamber at 2.337

2 pics of each side of bullet after “jam” note the new ring.

For reference the round from my original post was CBTO of 2.300 so I should be 37 thou off the lands.

Using Hornady bullet comparator before “jam” CBTO measures 2.432.

Pic of bullet sharpied up. Note the ring from bullet comparator.

Now jam measurement after seating in chamber at 2.337

2 pics of each side of bullet after “jam” note the new ring.

For reference the round from my original post was CBTO of 2.300 so I should be 37 thou off the lands.

- Thread Starter

- #30

OP

Outdoorsman12b

WKR

- Joined

- Sep 24, 2018

- Messages

- 552

- Thread Starter

- #31

OP

Outdoorsman12b

WKR

- Joined

- Sep 24, 2018

- Messages

- 552

Original post was in haste at the range. To further elaborate one of the reasons this ring concerns me is over a hunt I will chamber the same round over and over. It’s clear to me that this ring is wear on the jacket of the bullet and I would like to avoid the possibility of a bullet failure due to inconsistency in the jacket. This may not be a real thing to worry about but for me it is worth flushing out.

Thanks again for feedback so far.

Thanks again for feedback so far.

- Thread Starter

- #33

OP

Outdoorsman12b

WKR

- Joined

- Sep 24, 2018

- Messages

- 552

Just whatever is in the standard RcBS die.Are you using a VLD seater stem?

There’s your problem.Just whatever is in the standard RcBS die.

- Thread Starter

- #35

OP

Outdoorsman12b

WKR

- Joined

- Sep 24, 2018

- Messages

- 552

Can you elaborate? There is no mark on the bullet after seating and it appears on the eldx as well. Are you saying the VLD seater stem would prevent the ring when chambering in both circumstances?There’s your problem.

Last edited:

BBob

WKR

You could reload that thing 20 times and it won’t make a difference or make the jacket fail. It’s very obvious it’s the shank of the bullet entering the throat and you’ve shown you’re off the lands. You also stated it chambers fine with no resistance. I see this all the time especially on a freshly chambered barrel or a new gun.This may not be a real thing to worry about but for me it is worth flushing out.

I didn’t read your whole thread. I don’t know what you mean by free seating. All I’m saying is that exact ring around the bullet mark is a very common and known issue caused by seating secant ogive bullets (VLDs) in seating dies designed for tangent ogive bullets (most of them). The fix is to swap out the seater stem.Can you elaborate? There is no mark on the bullet free seating and it appears on the eldx as well. Are you saying the LD seater stem would prevent the ring when chambering in both circumstances?

Akblazer45

FNG

I’ve seen a few people test accuracy of seating depth as well. I can’t find it but I seem to remember .030-.050 off the lands had the best accuracy.There was a study on this I read a while back that indicated seating depth (assuming not jammed) had an insignificant impact on pressure but throat length or freebore had a significant impact. Enough that I don't even consider seating depth impacts on pressure anymore loading off the lands and not at max pressures.

I can't find the damn thing now..

Here's how my simple mind thinks about it - it takes some pressure to expand the case and case neck to release the bullet but not near peak SAAMI pressures. It makes sense to me that pressures would rise faster if the bullet is seated deep in the case reducing the space for the initial "explosion" to occur in. Once the bullet is released from the case it moves forward without resistance until squeezed by the lands - the space behind the bullet when it meets resistance from the lands is a different capacity independent of where it was seated in the case and seems reasonable that it would have a larger impact on peak pressures.

Edit: found other studies contradicting the above where seating depth has a clear impact on pressure. Note that in the graph below seating deeper only DECREASED pressure until bullet was seated over 0.250" from the lands. It makes me wonder how much load density impacts the results.

View attachment 493799

It’s not scientific and absolutely varies per firearm I would imagine.

- Thread Starter

- #39

OP

Outdoorsman12b

WKR

- Joined

- Sep 24, 2018

- Messages

- 552

Should have read “after” not free sorry.I didn’t read your whole thread. I don’t know what you mean by free seating. All I’m saying is that exact ring around the bullet mark is a very common and known issue caused by seating secant ogive bullets (VLDs) in seating dies designed for tangent ogive bullets (most of them). The fix is to swap out the seater stem.

Pickettpuncher

WKR

- Joined

- Nov 12, 2020

- Messages

- 1,403

It’s really not. The standard rcbs seater doesn’t contact the bullet that far down. It will contact just below the red tip.There’s your problem.

Similar threads

- Replies

- 2

- Views

- 400

- Replies

- 7

- Views

- 507

Featured Video

Stats

Latest Articles

-

TT#47 Draw Strategies with Robert Hanneman

-

Ultralight Tripods, Tested and Reviewed

-

Bowhunting Accuracy: Arrow Speed vs. Weight

-

Net-Gunning for Big Mule Deer

-

Tricer JC and Tricer BP Review

-

Best Gear of 2024

-

Best Gear of 2024 Rokslide Edition

-

TT#46 NRL Hunter with Travis Ishida, Justin Crossley, and Travis Bertrand

-

Argali Alpine Sleeping Bags Review

-

Conservation Easements for Big Bucks