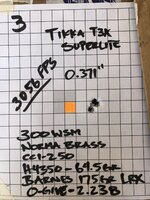

What’s going on? 300wsm Norma brass, annealed using torch and driver with socket. Full length sized with Redding type s .333 bushing. Shoulder bump .002, Wet tumbled.

Issue started when I tried to use a hornady VLD seating stem in a hornady custom seating die. I did notice i had to use more force when seating, a lot more force. Prior to changing the seating die, it was fine, even with my annealing. I did put the original seating stem back in but it keeps destroying my brass. I just ordered a Redding competition seating die and .334 bushing, hoping that will fix my issue. Any thoughts?

Issue started when I tried to use a hornady VLD seating stem in a hornady custom seating die. I did notice i had to use more force when seating, a lot more force. Prior to changing the seating die, it was fine, even with my annealing. I did put the original seating stem back in but it keeps destroying my brass. I just ordered a Redding competition seating die and .334 bushing, hoping that will fix my issue. Any thoughts?