Good day all! I had a custom barrel put onto my Sako A7. I dont want to throw any companies u der the bus until they have had a chance to respond to my service request (submitted to their web customer service already).

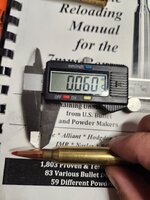

Here is the question. I had a barrel made for me and a prefit chambering for 7mm rem mag. The barrel went on smoothly and was checked with gauges. All work was by a very qualified gunsmith. He mentioned the length to the rifling was long. I had been having accuracy issues with several factory loads and my own loads. So i took the gun back to him and he measured 3 different bullets with the hornady modified case tool. What we found was a COAL from 3.535 ro 3.685 to touch the rifling. All were 175 gr bullets from differents makes. Now the 7mm rem mag has a saami spec of 3.29 as max and anything longer does not fit my mag.

So the two questions I have: is this an obvious cause for accuracy inconveniences, basically a .245 jump? And is this way out of spec for a new barrel? It will only get worse as the bore erodes. What would you expect from the barrel maker?

Here is the question. I had a barrel made for me and a prefit chambering for 7mm rem mag. The barrel went on smoothly and was checked with gauges. All work was by a very qualified gunsmith. He mentioned the length to the rifling was long. I had been having accuracy issues with several factory loads and my own loads. So i took the gun back to him and he measured 3 different bullets with the hornady modified case tool. What we found was a COAL from 3.535 ro 3.685 to touch the rifling. All were 175 gr bullets from differents makes. Now the 7mm rem mag has a saami spec of 3.29 as max and anything longer does not fit my mag.

So the two questions I have: is this an obvious cause for accuracy inconveniences, basically a .245 jump? And is this way out of spec for a new barrel? It will only get worse as the bore erodes. What would you expect from the barrel maker?