Lawnboi

WKR

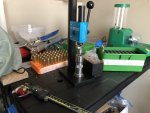

Well after over a year of scouring the net including this site for information on reloading, I finall put together some equipment and am off to the races. Going to post in this thread for the next few weeks as I attempt to build a few loads. Any input is greatly appreciated. I’m hoping to get my ES/SD down, and have a little more consistency than factory ammo. I went a little beyond buying a starter set, as I wanted gear I wasn’t going to grow out of quickly. That said I still have a long list of stuff I think I’ll need.

For starters, I’m going to reload some 223. Iv got 600 pieces of once fired hornady brass, and 200 Lapua never fired. Going to start with the hornady, since I won’t mind messing up one or two, or a hundred.

Alright here we go. Brass prep time. I started by counting out around 200 pieces of brass, cracked open the box on a hornady dry tumbler that UPS delivered this morning, and threw in some rice and let it go for an hour.

Rice seemed to do its job, came out pretty clean. Iv read the debates on wet vs dry, and squeaky clean brass vs somewhat dirty. Figured I’d eventually need a dry tumbler so why not start there. Went with rice for starters to attempt to keep dust down, seems to be working so far.

Next up it was sizing. This hornady brass was all over the place for size and neck thickness. I took the shortest brass, using a hornady headspace comparator, and mitutoyo calipers and set myself up for a small bump on most brass. Initial measurements yielded +\- .004, took the bottom one that chambered easily at 1.4580 and attempted to replicate. For reference my modified hornady case for my comparator is 1.4570. Neck thicknesses were all over as well, didn’t help most were dented. My tikka must be spitting them out pretty hard. Little math and I landed on a .246 bushing in my die. I purchased an LE Wilson set with their full length bushing sizer, set it up to bump to my shortest brass, and began sizing. I initially wanted Redding competition shell holders to play with adjustment that way, but they are sold out everywhere so

For lubricant I ran imperial sizing wax on the body, and dipped the case mouth in imperial dry neck lube. Nothing got stuck but I dented a few, learned quick that a little of that wax goes a long way. Anyways I didn’t worry much about the dented mouths for starters, as I planned to run my brass through an expander mandrel to push any imperfections to the outside of the case.

I continued to size the 200 I had, checking periodically, everything was remaining what I thought was pretty consistent. So I sized them all.

Following sizing I deburred flash holes, probably totally unnecessary for what I’m trying to accomplish but threw it in there. Also cleaned up primer pockets with a lee cleaner chucked up on a drill. Worked well, pickets came out looking okay.

After sizing and cleaning I threw the brass back in the tumbler to get the wax off, 20 minutes and I took it out.

Next I set up my press with a Sinclair expander mandrel to smooth out my necks, and hopefully set a nice consistent neck tension. I have a turning mandrel somewhere in USPS land coming that I was also going to play with, but for now I’m just using the expander hoping it will give me enough tension.

I ran all the brass threw the mandrel, lubing with imperial dry lube periodically. Very little resistance on the mandrel told me that I probably did the right stuff picking my bushing. Pressure needed to expand was all over the board. Some cases took almost nothing, some a bunch, I’m guessing it’s just from hornady neck thicknesses being all over the place.

Once expanded it was time to trim. I grabbed a Giraud tri way for this, trim/chamfer/debur all in one step. I left it set to it’s factory setting at 1.7435” and started trimming. Some sore fingers later and I had everything trimmed up. Checking periodically the trimmer was doing a great job, my cases were all 1.743-1.744”.

Called it a night, brass should be ready for primers, powder and bullets.

Anything I’m missing so far?

For starters, I’m going to reload some 223. Iv got 600 pieces of once fired hornady brass, and 200 Lapua never fired. Going to start with the hornady, since I won’t mind messing up one or two, or a hundred.

Alright here we go. Brass prep time. I started by counting out around 200 pieces of brass, cracked open the box on a hornady dry tumbler that UPS delivered this morning, and threw in some rice and let it go for an hour.

Rice seemed to do its job, came out pretty clean. Iv read the debates on wet vs dry, and squeaky clean brass vs somewhat dirty. Figured I’d eventually need a dry tumbler so why not start there. Went with rice for starters to attempt to keep dust down, seems to be working so far.

Next up it was sizing. This hornady brass was all over the place for size and neck thickness. I took the shortest brass, using a hornady headspace comparator, and mitutoyo calipers and set myself up for a small bump on most brass. Initial measurements yielded +\- .004, took the bottom one that chambered easily at 1.4580 and attempted to replicate. For reference my modified hornady case for my comparator is 1.4570. Neck thicknesses were all over as well, didn’t help most were dented. My tikka must be spitting them out pretty hard. Little math and I landed on a .246 bushing in my die. I purchased an LE Wilson set with their full length bushing sizer, set it up to bump to my shortest brass, and began sizing. I initially wanted Redding competition shell holders to play with adjustment that way, but they are sold out everywhere so

For lubricant I ran imperial sizing wax on the body, and dipped the case mouth in imperial dry neck lube. Nothing got stuck but I dented a few, learned quick that a little of that wax goes a long way. Anyways I didn’t worry much about the dented mouths for starters, as I planned to run my brass through an expander mandrel to push any imperfections to the outside of the case.

I continued to size the 200 I had, checking periodically, everything was remaining what I thought was pretty consistent. So I sized them all.

Following sizing I deburred flash holes, probably totally unnecessary for what I’m trying to accomplish but threw it in there. Also cleaned up primer pockets with a lee cleaner chucked up on a drill. Worked well, pickets came out looking okay.

After sizing and cleaning I threw the brass back in the tumbler to get the wax off, 20 minutes and I took it out.

Next I set up my press with a Sinclair expander mandrel to smooth out my necks, and hopefully set a nice consistent neck tension. I have a turning mandrel somewhere in USPS land coming that I was also going to play with, but for now I’m just using the expander hoping it will give me enough tension.

I ran all the brass threw the mandrel, lubing with imperial dry lube periodically. Very little resistance on the mandrel told me that I probably did the right stuff picking my bushing. Pressure needed to expand was all over the board. Some cases took almost nothing, some a bunch, I’m guessing it’s just from hornady neck thicknesses being all over the place.

Once expanded it was time to trim. I grabbed a Giraud tri way for this, trim/chamfer/debur all in one step. I left it set to it’s factory setting at 1.7435” and started trimming. Some sore fingers later and I had everything trimmed up. Checking periodically the trimmer was doing a great job, my cases were all 1.743-1.744”.

Called it a night, brass should be ready for primers, powder and bullets.

Anything I’m missing so far?