Since Sig introduced the 277 Fury with a Bimetal case, it is such an awesome idea. The main culprit is as to whether an action will handle it is bolt thrust . In modern day bolt guns .

It is not a problem to go to 70,000 plus psi. The limiting factor there is more in the casing. Brass casings swell under the pressure and first thing to go are primer pockets. Then blown primers and accompanying stiff bolt lifts. If there is too much head spacing you even risk case head separation.

All of these factors if not perfect just get you into trouble quicker the higher the pressure gets. So tolerances are absolutely critical. In guns built to handel such pressures, exact head spacing , throat and ammunition tolerance become critical as well so they are duplicated across platforms.

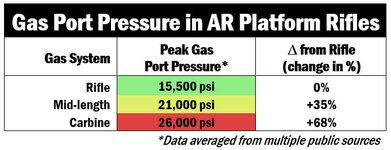

Gas guns are a whole new world, the main components with design are absolute mechanical strength and stress characteristics as well as increasing dwell times so that cases are left in battery longer allowing extraction with less pressure. From an engineering perspective I see these as doable in gas rifles, and in standard AR15’s with 385 bolt faces there is enough meat on the bolt to handle thrust at the 70,000 psi. Failed would occur at the bolt prongs that fort the extension and at the cam lug. By modifying gas gun buffer weights and springs, and using more exotic materials It could be made reliable and reasonably safe

Of course this does not apply to rounds with .441 faces like the Grendel or the ARC cases. The amount of meat left by increasing the internal bolt dimensions but leaving the exterior bolt and extension dimensions the same just make it very impractical unless you are using bolt and extension materials that make the bolt more expensive than the rifle itself.

In general I have imploded high pressure bolts , heavy buffers and springs with adjustable gas blocks which all are aimed at mitigating the resultant, dwell timing and increased bolt thrust . My guess is my warm loads are closing in on 60,000 psi. And I am sure there will be a bolt failure , either at a cam or one of the lugs at some point. But there is no way to even remotely approach 70,000 to 75,000 psi with that standard gas impingement system, the lugs in the 441 bolt face are just guaranteed to fail.

For AR10 models you can follow many of the above to extend operating pressures because you just have more mechanical heft as you have KAK making magnum faced bolts to operate in AR10’s. . So for standard AR10 .473 face , using impingement systems adjusting the variables can probably get you 65,000 or 70,000 psi but not 80,000 psi as in the Fury case.

The Sig Fury XM7 uses a short piston gas system, in which you have absolutely control of the forces working on the opening and closing of the bolt. For high pressure AR’s it would appear that from an engineering perspective this is the way to go.

So I am betting the 70,000 to 75,000 psi pressures 5.56 rounds can be handled in a AR15 platform with specific components , buffers, springs and bolts however in my honest opinion regardless of what anybody says, I would opt for a short or long stroke piston system.

This can not be carried over to the Grendel / ARC cartridges because without going to super expensive bolt materials , and machining processes, which I imagine could be done but some exotic materials probably using electric dialysis chemical machinery. Would make the rifle $1,500 and the bolt $5,000 each.

Or create a totally separate barrel extension and bolt for these face cartridges using standard currently machined material and techniques. Of course this would increase the price of these type gas rifles say by a factor of $500 more for the internals.

Currently I have my 24” Grendel pushing 100 gr ELD VT bullets at 2,900 fps. Upping another 10,000 or 15,000 psi and it probably hovering at 3,300 fps with 3,000 out of a 16” Now that would be a mean round 130 gr Berger hybrids at almost 2950 from a 24 and 2,700 from a 16”.

But again I would opt for redesign the bolt and extension and then make the rifle a short stroke piston gun. It is a crazy world though 6.5 Grendel’s pushing bullets at or beyond 6.5 Creedmoor conventional rifles. That would really be the shit.

The manufacturers will keep making this technology available as long as they can make it at an incremental price increase over conventional case and rifle design.

I already started using 277 Fury Sig cases in my 260 rem and 308 win gas and bolt guns. Why because now I can run warm loads for long heavy long range bullets and the primer pockets aren’t shot after 2 reloads. Just recently started reloading I have some twice fired the look good as new.

What will be next.

Sent from my iPhone using Tapatalk

le.vistaoutdoor.com