Anyone got a personal use drawing, or PDF for limb fingers for a diy bow press?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY Press Drawings/PDF?

- Thread starter Stubborn_bowhunter

- Start date

Klooop

FNG

What size square tube did you use for yours?I haven't gotten there yet, but I planned on posting a full drawing set after verifying it fits with my Elite Kure.

It may be a while, so don't hold your breath!

In the mean time, I'm certainly interested to see what others have come up with as well.

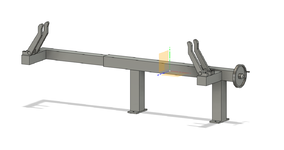

Here's a quick render of my progress.

View attachment 390435

I made a mockup rough draft of one on fusion 360 last night. I'll post it up when I have time.

Klooop

FNG

This was also done in Fusion 360. The bulk of it is 1.5"x.120" square tube.What size square tube did you use for yours?

I made a mockup rough draft of one on fusion 360 last night. I'll post it up when I have time.

I have 1.25" square tube telescoping inside of the 1.5" but that probably won't be easy to do. Usually this tubing has a seam inside, so I'll have to remove that - I think the Fireball Tool youtube channel has a good video on this if you're interested. It would be easier to do a 1.0" tube and weld in some spacers/reducers, but I think that would always bug me. True telescoping tubes will reduce binding and provide more complete support.

I have a left over acme lead screw & nut that I should be able to fit in there just fine. Modelling those parts up and designing a bearing block is my next step.

Mighty Mouse

WKR

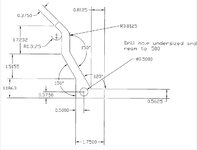

Here's a design someone posted in an old Archery Talk thread:Anyone got a personal use drawing, or PDF for limb fingers for a diy bow press?

Coopsdaddy

WKR

Really wouldn’t it be easier just to buy one?im all for saving money but they can found for 400,buy the time your finished i bet you wouldn’t save 200.

Billy Goat

“MOMMY”

This was also done in Fusion 360. The bulk of it is 1.5"x.120" square tube.

I have 1.25" square tube telescoping inside of the 1.5" but that probably won't be easy to do. Usually this tubing has a seam inside, so I'll have to remove that - I think the Fireball Tool youtube channel has a good video on this if you're interested. It would be easier to do a 1.0" tube and weld in some spacers/reducers, but I think that would always bug me. True telescoping tubes will reduce binding and provide more complete support.

I have a left over acme lead screw & nut that I should be able to fit in there just fine. Modelling those parts up and designing a bearing block is my next step.

You need to find extruded square tube. It doesn't have a weld seam.

Unless you have access to all the equipment, you really are better to buy. I use to design/fab a good bit. It's time consuming, and lots of times the first prototype you miss something, causing you to build or heavily modify the first iteration.

It's going to be real expensive when you don't realize the design flaw til it's too late.

Below 200 for everything right now. If I could find a used one for a fair price I'd probably do it.Really wouldn’t it be easier just to buy one?im all for saving money but they can found for 400,buy the time your finished i bet you wouldn’t save 200.

Fabricating stuff is fun though too.

In my mission to find some limb fingers for my own I've found that Last Chance has gone after anyone who sells them, and they refuse to provide replacements to people.

Idk about buying shit from a company like that.

But if I see a ez green cheaper I'll probably jump.

Last edited:

OctoberGold

Lil-Rokslider

There's a set of fingers on AT for sale right now. $70 for 4.

Went to jump on that, but he's in Canada and the shopping probably puts it up past 100 lolThere's a set of fingers on AT for sale right now. $70 for 4.

Billy Goat

“MOMMY”

Below 200 for everything right now. If I could find a used one for a fair price I'd probably do it.

Fabricating stuff is fun though too.

In my mission to find some limb fingers for my own I've found that Last Chance has gone after anyone who sells them, and they refuse to provide replacements to people.

Idk about buying shit from a company like that.

But if I see a ez green cheaper I'll probably jump.

So you don't think they should have the rights to something they came up with?

Do you know how many companies just in the archery industry have gone under from other companies replicating their designs?

BBob

WKR

Like it or not they do have a patent on them and that's an investment right there. How many presses would they need to sell to cover legal costs? Probably quite a few and all and all I'll bet the bow press market isn't a huge market compared to other things in life.Idk about buying shit from a company like that.

Two patents exist:

Last edited:

Nah. I've seen a lot that they won't even sell replacements at risk of someone making their own press.So you don't think they should have the rights to something they came up with?

Do you know how many companies just in the archery industry have gone under from other companies replicating their designs?

Seems to me they could make a good amount of money selling limb fingers alone.

I'm not trying to argue the patent ownership.

Just looking for press and limb contact point designs. Not trying to sell shit. Looking into fabricating my own press.

Edit: and I did say I'd buy one of these things used if they ever came up. Most of the time they're out of stock everywhere.

Sometimes making shit is the best option.

Last edited:

Billy Goat

“MOMMY”

Nah. I've seen a lot that they won't even sell replacements at risk of someone making their own press.

Seems to me they could make a good amount of money selling limb fingers alone.

I'm not trying to argue the patent ownership.

Just looking for press and limb contact point designs. Not trying to sell shit. Looking into fabricating my own press.

Edit: and I did say I'd buy one of these things used if they ever came up. Most of the time they're out of stock everywhere.

Sometimes making shit is the best option.

When you have issues with their products, they fix it.

They sell updated fingers to you when you have their product.

Find a fabrication shop and have them laser cut fingers out of 3/8" steel. McMaster Carr has nestable tubing. Bearings, 5/8" acme rod, and your handle can all be found on ebay for cheap. There are some good designs already on the internet. If you know someone in a CNC or metal fab shop you're set. The fingers are the only thing you really can't fab on your own. Too inconsistent. Mine turned out well. I also fabbed a draw board.

Attachments

quinnjalan

FNG

- Joined

- Mar 3, 2022

- Messages

- 21

I was a welder for over 20 years and I'm currently a designer. I kicked around the idea of building one and didn't as the price of the stock, screw, bolts, fingers and my time out weighted the cost of just buying one. Keep in mind I always try to build something rather than buying but in this case I could not justify it. Perhaps if I have retired or semi retired and needed something to do it would be a different story. Good luck on your build.

I bought some fingers off of AT and built my own. Actually I built two and sold one for $400 but if I was to do it again I would just buy one. It was only a day to make them but after material costs I don’t think it’s worth it.

I only built two because the first set of fingers got lost in the mail and showed up 7+ months after a claim was put in and a new set shipped out. The postage and exchange rate plus materials made me make very little money after selling the extra one. It’s great that it paid for itself but it was only because of the extra set of fingers

I only built two because the first set of fingers got lost in the mail and showed up 7+ months after a claim was put in and a new set shipped out. The postage and exchange rate plus materials made me make very little money after selling the extra one. It’s great that it paid for itself but it was only because of the extra set of fingers

Dschwan

WKR

I sent you a PMAnyone got a personal use drawing, or PDF for limb fingers for a diy bow press?

iowathumpr

FNG

- Joined

- Aug 30, 2023

- Messages

- 6

What bearing do we need, you have any pictures of how the acme rod assembly all attaches to the frame?Find a fabrication shop and have them laser cut fingers out of 3/8" steel. McMaster Carr has nestable tubing. Bearings, 5/8" acme rod, and your handle can all be found on ebay for cheap. There are some good designs already on the internet. If you know someone in a CNC or metal fab shop you're set. The fingers are the only thing you really can't fab on your own. Too inconsistent. Mine turned out well. I also fabbed a draw board.

Similar threads

- Replies

- 14

- Views

- 528

- Replies

- 8

- Views

- 348

Featured Video

Latest Articles

- TT#64 Josh Boyd Elk Hunting Strategies for Every Season

- Aaron Davidson of Gunwerks

- TT#63 Dirk Durham’s Art of Elk Calling

- BIG Buck Stories with the Dirty Giants Podcast

- TT#62 Brian Barney Hunting Bulls without Calling

- Hoyt Alpha AX-2 SD Review

- Kuiu Kenai vs Outdoor Vitals Vario Hooded Jacket Review

- Hoyt RX-9 Ultra Review

- Hunting Vampire Bucks & Building an Optics Kit

- Darton Sequel ST2 35 Review