Beendare

"DADDY"

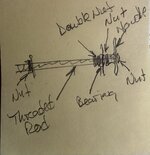

Its pretty intuitive….I bought everything for mine from Mcmaster carr inc the nested pipe sections. I went with a threaded rod vs a screw jack which I regret.What bearing do we need, you have any pictures of how the acme rod assembly all attaches to the frame?