KelsoBrowny

FNG

- Joined

- Sep 17, 2018

- Messages

- 59

I thought about making this post, and decided to go for it since I figure there's someone else out there wondering if they could do a DIY Pre-Fit Custom. If I can do it, you can.

Last summer, a family friend got me into long(er) range shooting. Helped me work up a load for my rifle (.3” @ 100), and got me shooting 8” groups at 1000 yards. And while I loved my Browning Hells Canyon Speed I wanted a different stock, better trigger, longer coal, twist for 180gr Bergers - and being 22 around my dads RBros, that family friend’s myriad of customs - I was enthralled by the idea of a shiny new rifle, emboldened by the tips of a college bar job

So I started looking into customs. My wallet clenched. Next I looked at Tikka’s thanks to the semi-custom thread - but with my dad shooting a 7mm mag, and the man reloading for me primarily shooting a 7mm Mag (which his components he offered to share) I was pretty set on that caliber - and I chose not a Tikka due to the potential COAL limitations wanting to shoot 180’s and maybe 195’s. Then I found out about pre-fits and so began my deep, deep dive into some research. Now, I'm not an idiot. But back in HS if my buddies were getting together to work on a truck, I was in charge of laps to the fridge. My mechanical skills aren't pretty, but I can follow instructions. So in my research I found out my various options - cost versus weight, what would work with what components — and while I didn’t want a heavy rifle - financially right now, the additional $600 to cut 1# off the stock, I could’ve found another piece of my gear to cut that for less. And then one night comparing costs, and checking availability I found one of the actions was available on a pre-order with a release in 2 days. And then the matching barrel was on sale on another site. And so I decided to send it.

Defiance Tenacity Stainless Long Action Magnum $960.00

FFL Transfer on the Action. $ 25.00

Proof Carbon Prefit 7mm Rem Mag 24” 1-8.4. $989.09

Trigger Tech Special for Remington 700 $ w/above

AI .300 3RD SSF CIP Length Magazine $94.81

KRG Bravo Rem 700 Long Action $447.23

-------------------------------------------------------------------

$2,516.04 Gun Parts (with shipping and Tax)

Viper Barrel Vice $155.85

PSG Remington 700 Action Wrench w/above

Automotive Torque Wrench $ 42.50

Hand Torque Wrench $ Free (Thanks Dad)

Headspace Gages $35.00

-------------------------------------------------------------------

$2,749.39 After Tools (with shipping and Tax)

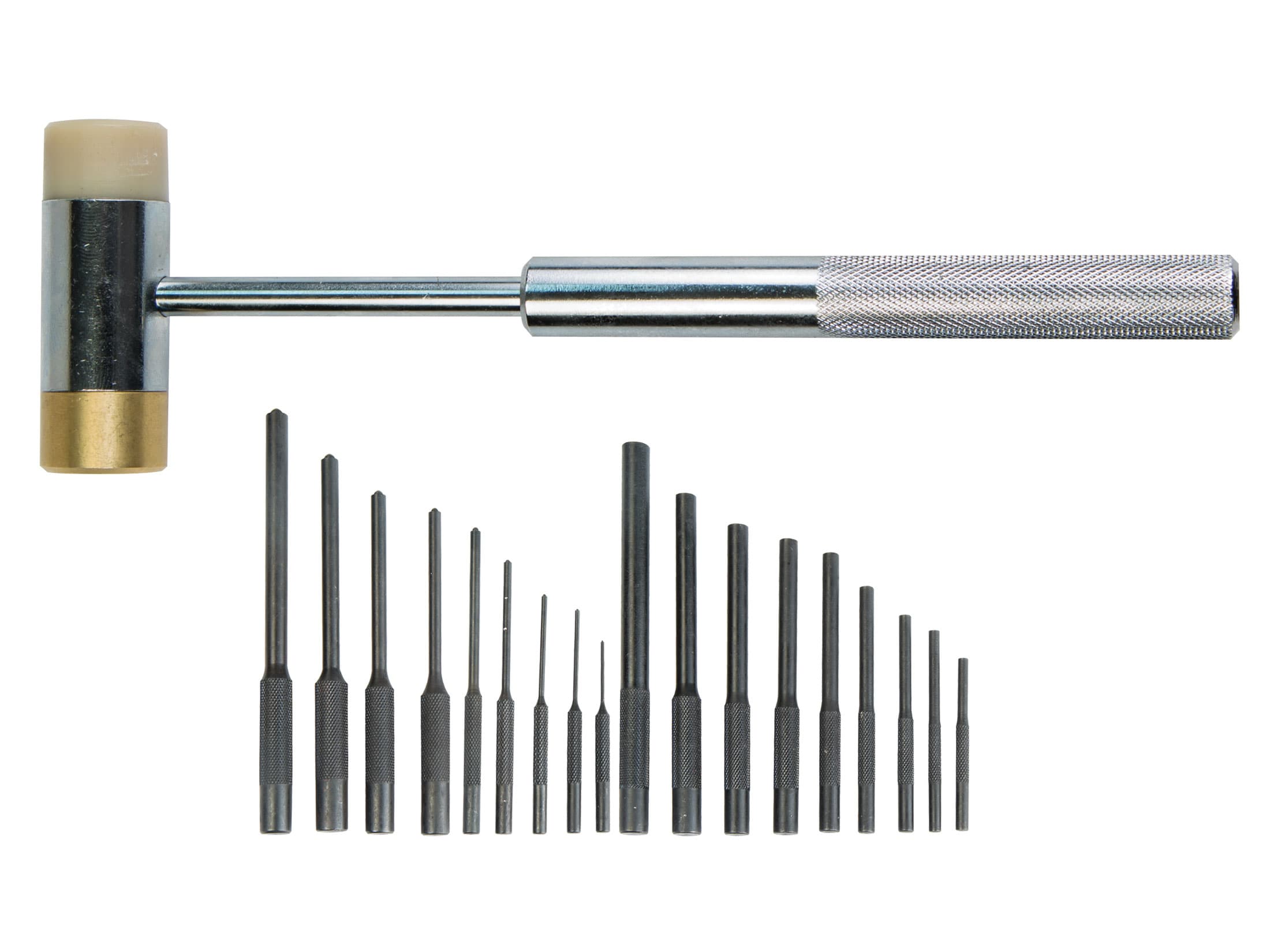

Within two weeks, everything but the rented gauges came since I didn’t want them to arrive before I could start my build and have to pay more. Keep in mind, I’m in a college style house without a garage. Attached to my bedroom is weird basement/mechanical room without a light, that had an old wooden table attached to the wall (that I lit with an extension cord and a lamp). Using (my roommates) drill bit that’s three times smaller than the vice bolts, I punched holes in the wood until they fit. Attached the vice to the table. Wrapped the steel part of the proof barrel in notebook paper, tightening down the bolts on the side opposite the carbon most. Hand tightened the action to the barrel. Set the automotive torque wrench to (I believe defiance specs are 75 ft-lbs), and torqued. Retightened barrel vice since it slipped. And torqued until the wrench popped. It took me 3x longer to drill out the vice holes than attach the barrel. I then took the barreled action to the desk in my bedroom, and used a Pilot G2 pen to tap the 2 pins to get my trigger into the action. Setting the stock on my office chair, and resting the barrel on the my desk, I used the hand torque wrench to tighten the stock into the action. This was a bit of a pain, as my bit had too fat of a base too fit, so I ended up boring the hole out a bit to fit the hex bit. But 87 minutes after I grabbed my roommate drill, I had a built rifle. Ran both factory and my hand-loaded 7mag rounds through the mag to make sure they fed. Did the slam and lighten method on my trigger to make sure it was safe. Everything felt solid. The only thing I did was then have to wait 2 more days for the headspace gauges to arrive since I was impatient on building it. Put In the go gauge. Closed the bolt. Put in the no go gauge. Prayed, It wouldn’t close. It didn’t. Final weight on the rifle is somewhere between 8.5-9 pounds (My bathroom scale with me on it, then rifle, alternates between the two).

Basically, this post, is to tell you - yes you can build a custom gun. It is as easy as people make it seem. That being said, it’s getting it’s first range trip this coming week in which I’ll share my accuracy results if I don’t blow off my typing hand. Even before firing though - I would’ve changed a few things - I would’ve spent the extra few hundred to go with a lighter action considering how long I’m going to keep it (however component availability factored into it heavily). I also would’ve gone with a lighter stock, but it is a budget build and I could always buy a new one - but I’ll always be stuck with the heavier action. Also, would’ve gone BDL, the AICS mag rattles just enough I know it’ll bother me a hair.

Last summer, a family friend got me into long(er) range shooting. Helped me work up a load for my rifle (.3” @ 100), and got me shooting 8” groups at 1000 yards. And while I loved my Browning Hells Canyon Speed I wanted a different stock, better trigger, longer coal, twist for 180gr Bergers - and being 22 around my dads RBros, that family friend’s myriad of customs - I was enthralled by the idea of a shiny new rifle, emboldened by the tips of a college bar job

So I started looking into customs. My wallet clenched. Next I looked at Tikka’s thanks to the semi-custom thread - but with my dad shooting a 7mm mag, and the man reloading for me primarily shooting a 7mm Mag (which his components he offered to share) I was pretty set on that caliber - and I chose not a Tikka due to the potential COAL limitations wanting to shoot 180’s and maybe 195’s. Then I found out about pre-fits and so began my deep, deep dive into some research. Now, I'm not an idiot. But back in HS if my buddies were getting together to work on a truck, I was in charge of laps to the fridge. My mechanical skills aren't pretty, but I can follow instructions. So in my research I found out my various options - cost versus weight, what would work with what components — and while I didn’t want a heavy rifle - financially right now, the additional $600 to cut 1# off the stock, I could’ve found another piece of my gear to cut that for less. And then one night comparing costs, and checking availability I found one of the actions was available on a pre-order with a release in 2 days. And then the matching barrel was on sale on another site. And so I decided to send it.

Defiance Tenacity Stainless Long Action Magnum $960.00

FFL Transfer on the Action. $ 25.00

Proof Carbon Prefit 7mm Rem Mag 24” 1-8.4. $989.09

Trigger Tech Special for Remington 700 $ w/above

AI .300 3RD SSF CIP Length Magazine $94.81

KRG Bravo Rem 700 Long Action $447.23

-------------------------------------------------------------------

$2,516.04 Gun Parts (with shipping and Tax)

Viper Barrel Vice $155.85

PSG Remington 700 Action Wrench w/above

Automotive Torque Wrench $ 42.50

Hand Torque Wrench $ Free (Thanks Dad)

Headspace Gages $35.00

-------------------------------------------------------------------

$2,749.39 After Tools (with shipping and Tax)

Within two weeks, everything but the rented gauges came since I didn’t want them to arrive before I could start my build and have to pay more. Keep in mind, I’m in a college style house without a garage. Attached to my bedroom is weird basement/mechanical room without a light, that had an old wooden table attached to the wall (that I lit with an extension cord and a lamp). Using (my roommates) drill bit that’s three times smaller than the vice bolts, I punched holes in the wood until they fit. Attached the vice to the table. Wrapped the steel part of the proof barrel in notebook paper, tightening down the bolts on the side opposite the carbon most. Hand tightened the action to the barrel. Set the automotive torque wrench to (I believe defiance specs are 75 ft-lbs), and torqued. Retightened barrel vice since it slipped. And torqued until the wrench popped. It took me 3x longer to drill out the vice holes than attach the barrel. I then took the barreled action to the desk in my bedroom, and used a Pilot G2 pen to tap the 2 pins to get my trigger into the action. Setting the stock on my office chair, and resting the barrel on the my desk, I used the hand torque wrench to tighten the stock into the action. This was a bit of a pain, as my bit had too fat of a base too fit, so I ended up boring the hole out a bit to fit the hex bit. But 87 minutes after I grabbed my roommate drill, I had a built rifle. Ran both factory and my hand-loaded 7mag rounds through the mag to make sure they fed. Did the slam and lighten method on my trigger to make sure it was safe. Everything felt solid. The only thing I did was then have to wait 2 more days for the headspace gauges to arrive since I was impatient on building it. Put In the go gauge. Closed the bolt. Put in the no go gauge. Prayed, It wouldn’t close. It didn’t. Final weight on the rifle is somewhere between 8.5-9 pounds (My bathroom scale with me on it, then rifle, alternates between the two).

Basically, this post, is to tell you - yes you can build a custom gun. It is as easy as people make it seem. That being said, it’s getting it’s first range trip this coming week in which I’ll share my accuracy results if I don’t blow off my typing hand. Even before firing though - I would’ve changed a few things - I would’ve spent the extra few hundred to go with a lighter action considering how long I’m going to keep it (however component availability factored into it heavily). I also would’ve gone with a lighter stock, but it is a budget build and I could always buy a new one - but I’ll always be stuck with the heavier action. Also, would’ve gone BDL, the AICS mag rattles just enough I know it’ll bother me a hair.