Chris in TN

WKR

- Joined

- Jun 17, 2025

- Messages

- 1,533

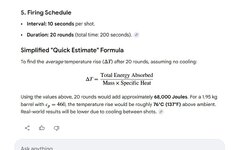

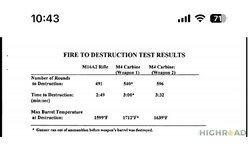

My understanding of thermal shock is that it would maybe, possibly be an issue if you'd mag-dumped your AR a few times in summer then sent it swimming.Extreme temperature gradients across a piece of metal, particularly if the outside is much colder than the inside, can cause the thermal stresses to exceed the yield stress, i.e. the metal ruptures. This is compounded if you are trying to simultaneously contain something that is very high pressure, the metal is very thick, and the temperature difference across the metal is large. The concerns guys are raising have roots in very real material science.

Those having success cold quenching hot barrels may be right that it is safe, long term in all circumstances, I'm not doing any math on the situation to prove otherwise. But there is a clear path to a material failure at the extreme limits of this approach.

Thermal Shock (Thermal Stress) | Engineering Library

This page provides the chapters on thermal shock (thermal stress) from the DOE Fundamentals Handbook.engineeringlibrary.org

But do note that this whole diversion started because Form suggested I put water on my muzzleloader barrel. The delta between a room-temperature bottle of water I might have in the barn in summertime and the internal temperature of the bore - when hot enough to cause issues with plastic sabots - would likely be well under 50 degrees. It takes almost nothing in terms of heat, to be a problem with soft muzzleloader sabots. It's a real pain in summer. Which is why I sometimes stick the things in my deep freezer. Also, I don't have running water in the barn, nor a drain if I were to pour it out. So I'll probably keep using the freezer. Muzzleloader load testing in summer isn't exactly a high-speed endeavor.

Gemini says you'd need to be at 450+F for it to be a problem. That's for barrels, not the can. I didn't ask about cans but I can see where a 3d printed Ti can might get hot enough to be a thing.