TaperPin

WKR

- Joined

- Jul 12, 2023

- Messages

- 6,317

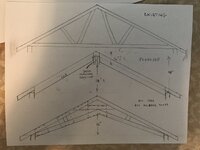

Exposed structural timber trusses that have been engineered and built to be self supporting look awesome and no ridge needed. You would have to strip all the old roof off to get them in, and they would be many times the cost of new scissor trusses, and the 2x6 T&G to span between them looks awesome and makes my wallet hurt just looking at it - $2 to $10 a linear foot, then the roof 2x sleepers, insulation, and osb on top of that makes for a spendy roof. If scissor trusses seem expensive, these definitely are not in the budget. If you want a T&G ceiling it’s cheaper to have a ridge beam and apply 1” T&G over the rafters.

Last edited: