cjc5062

FNG

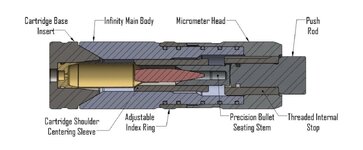

Hi all, I upgraded my whole reloading setup recently and just got everything set up. Using an Amp Annealer, Amp Arbor Press, Short Action Customs Infinity in-line Seating Die, Area 419 Zero Gen II press (for sizing), Area 419 M series FL sizing dies, Accuracy One Concentricity gauge, and Henderson Trimmer.

I'm trying to squeeze every little bit of accuracy out of my rounds. I know all this isn't necessary, but it's my hobby and I enjoy trying to chase every minuscule imperfection.

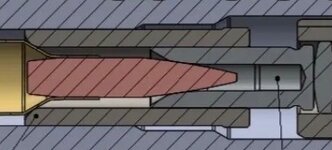

I recently loaded up some new cases (Peterson) and am not thrilled with the bullet Concentricity. I got anything from 0.001" to 0.004" on my bullet Concentricity. I anneal, full length size, trim and then seat using the arbor press and in-line seating die. For 6.5PRC I'm using the standard SAC neck guide with the M2 seating sleeve as recommended from SAC.

I believe my process is pretty dialed in, but the only thing I can think about is whether the fact I'm compressing powder for these rounds is making me get slight variations in runout? I've also measured my neck Concentricity and am getting .0005" runout on the neck, which should be great.

Appreciate any help!

I'm trying to squeeze every little bit of accuracy out of my rounds. I know all this isn't necessary, but it's my hobby and I enjoy trying to chase every minuscule imperfection.

I recently loaded up some new cases (Peterson) and am not thrilled with the bullet Concentricity. I got anything from 0.001" to 0.004" on my bullet Concentricity. I anneal, full length size, trim and then seat using the arbor press and in-line seating die. For 6.5PRC I'm using the standard SAC neck guide with the M2 seating sleeve as recommended from SAC.

I believe my process is pretty dialed in, but the only thing I can think about is whether the fact I'm compressing powder for these rounds is making me get slight variations in runout? I've also measured my neck Concentricity and am getting .0005" runout on the neck, which should be great.

Appreciate any help!