Jesse Jaymes

WKR

Took my Sunday to further load development and check zero. Had some serious horizontal stringing with an accurate Bergara and Mark 5HD. Both should be known and accurate. After some frustration I checked ring screws. They were not "finger tight" but I was able to add over half turn to them rather easily. They were installed w torque wrench to spec.

Ring to Base screws were tight but those are much higher torque with a 1/2" ratchet. Before totally removing scope I shot another group. 3 shots touched.

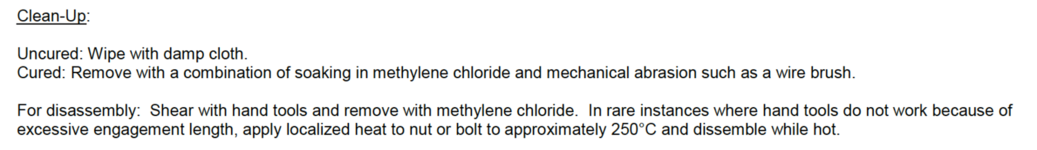

Asking if Blue Loctite is both Ok and should be "standard"? The scope is the 5-25X56. It's a big SOB on a brake-less 300 WM.

Ring to Base screws were tight but those are much higher torque with a 1/2" ratchet. Before totally removing scope I shot another group. 3 shots touched.

Asking if Blue Loctite is both Ok and should be "standard"? The scope is the 5-25X56. It's a big SOB on a brake-less 300 WM.