Just got a bitzenburger jig a few days ago, until now I have just fletched with Arizona EZ fletch. I purchased a straight clamp and will end up getting a helical at some point to play around with it.

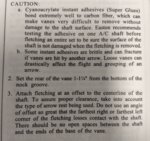

Questions are. How far from the nock are you fletching and are you measuring from the nock throat or the end of the arrow shaft?

Also how much offset should I be looking for and how can I tell how much I have?

Thanks

Questions are. How far from the nock are you fletching and are you measuring from the nock throat or the end of the arrow shaft?

Also how much offset should I be looking for and how can I tell how much I have?

Thanks