Another thing to consider is to buy the Sport (SPT) version of the Axis. Or even the normal non pro Axis. They are the exact same shaft but have a different straightness tolerance. It is marketed as a different shaft but they are not and 99% of us could never tell the difference if you prep using this method.

Spin each arrow and then cut off the end that has the most wobble. If no noticeable wobble cut from both ends. Using this method you can make a .006 tolerance arrow shoot the same as a .001.

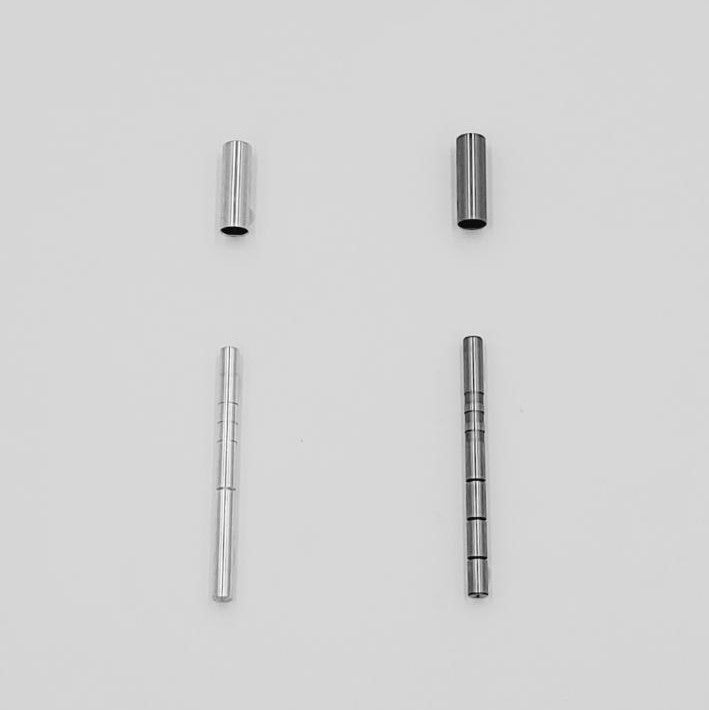

The cost might not seem significant but you'll save ~$95 per dozen. To be frank most .006 shafts from reputable companies spin well and I shoot broadheads out to 90 multiple times per week. I can't tell the difference. Also, another area you could save in the future is by using the new Ethics Archery HIT and Collar (they've had the collar for quite awhile but added the HIT).

Installation: For the Insert with End Cap, you will use the Installation Tool. Place the End Cap on, then the insert so you can install them at the same time. Make sure you dry fit the End Cap for proper fitment prior to gluing. *Installation Tool not included.

ethicsarchery.com

I roughly estimate that you can save $132 this way. Essentially building 2 dozen premium arrows for the same cost.

ethicsarchery.com