Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Are my arrows trashed?

- Thread starter Lark Bunting

- Start date

Lark Bunting

Lil-Rokslider

I guess this is a possibility. As of now they are the same diameter...probably because of the worn down coating.I suspect your point is slightly smaller than your shaft, the impact peeled outer layers.

These were supposed to be tips for the Axis 5mm arrows. I have used some that were slightly larger and it made pulling arrows out of the target a PITA.I've shot arrows into some pretty sketchy stuff over the years and never had an issue of carbon peeling away from the arrows.......even Axis arrows. Billy's comment makes sense. I've used tips slightly larger than the arrows, but never smaller.

Which outserts would you recommend? I'm about to order some more arrows and might have to change the option for "glued in inserts" for an extra charge.One of the reasons I like outserts with 4mm or 5mm shafts. Hidden inserts, D6 etc leave you more vulnerable to damage.

The broadhead collars? I have some, not sure how that would work though on a field point. Wouldn't that have a flat spot upon impact with the target? I'll experiment...You could always get some collars for them and they'll probably be fine.

Gorp2007

WKR

The broadhead collars? I have some, not sure how that would work though on a field point. Wouldn't that have a flat spot upon impact with the target? I'll experiment...

You can get an impact collar (Iron Will makes them along with others) that slips over the end and then just buy a field tip to match the outside diameter. That way the impact forces spread more evenly across the whole diameter of the arrow instead of catching an edge and peeling away carbon. They've definitely saved an arrow or two for me.

You can get an impact collar (Iron Will makes them along with others) that slips over the end and then just buy a field tip to match the outside diameter. That way the impact forces spread more evenly across the whole diameter of the arrow instead of catching an edge and peeling away carbon. They've definitely saved an arrow or two for me.

Footers are excellent for those smaller arrows. Moved to the hexx years ago and with the brass flush inserts they really distribute the impact well.

5MilesBack

"DADDY"

Great, are you telling me that I'm going to have to sand them down before hunting season to take the glare off them?I'm shooting victories now and they just get shinier and shinier the more you shoot them.

That's the one thing I hated about the Trophy Ridge arrows.......that glossy shiny coating they had on them. I used to have to put them in my drill and vise and run 600 grit carbide paper over them until the shine was gone. Otherwise the sun shined off them like a mirror.

Exactly what I was thinking?I wonder if there are some broken broad heads in the foam?

24on48hunting

WKR

You can foot your carbon arrows with a

1”- 2” piece of aluminum arrow shaft. I wouldn’t do it to a previously damaged arrow though.

I do this on my small game arrows and it makes them much more durable.

The GT carbons in the center are done that way. I bought those arrows in 2007 and they’re still as good as ever.

Easton 2117’s fit over them quite well, after a very light sanding on the inside of them. Sanding the inside of the footing also helps with adhesion.

I prefer to cut my footings 3/4” to 1” longer than my inserts. Once I cut the footings to length, I chuck them on a drill (very carefully so they don’t lose their shape) and spin them while filing a bevel on the front and the back. It takes a fairly steady hand and a little bit of practice to get the bevels even all the way around.

Filing the bevel allows them to enter and exit a target with ease, it also prevents unnecessary wear on the 3D target foam.

1”- 2” piece of aluminum arrow shaft. I wouldn’t do it to a previously damaged arrow though.

I do this on my small game arrows and it makes them much more durable.

The GT carbons in the center are done that way. I bought those arrows in 2007 and they’re still as good as ever.

Easton 2117’s fit over them quite well, after a very light sanding on the inside of them. Sanding the inside of the footing also helps with adhesion.

I prefer to cut my footings 3/4” to 1” longer than my inserts. Once I cut the footings to length, I chuck them on a drill (very carefully so they don’t lose their shape) and spin them while filing a bevel on the front and the back. It takes a fairly steady hand and a little bit of practice to get the bevels even all the way around.

Filing the bevel allows them to enter and exit a target with ease, it also prevents unnecessary wear on the 3D target foam.

Lark Bunting

Lil-Rokslider

Lots of good info, I appreciate it. New arrows, footers and different field points will coming soon.

24on48hunting

WKR

I forgot to mention trying a half-out insert if you can find them for your arrow of choice. If you do, run the footing all the way down over the entire insert.You can foot your carbon arrows with a

1”- 2” piece of aluminum arrow shaft. I wouldn’t do it to a previously damaged arrow though.

I do this on my small game arrows and it makes them much more durable.

The GT carbons in the center are done that way. I bought those arrows in 2007 and they’re still as good as ever.

Easton 2117’s fit over them quite well, after a very light sanding on the inside of them. Sanding the inside of the footing also helps with adhesion.

I prefer to cut my footings 3/4” to 1” longer than my inserts. Once I cut the footings to length, I chuck them on a drill (very carefully so they don’t lose their shape) and spin them while filing a bevel on the front and the back. It takes a fairly steady hand and a little bit of practice to get the bevels even all the way around.

Filing the bevel allows them to enter and exit a target with ease, it also prevents unnecessary wear on the 3D target foam.

View attachment 284977

If you need any help with building the footings, let me know.

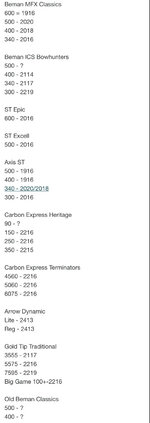

Attached is a few different arrows and the appropriate sized aluminum arrow needed for footing material.

If you shoot the Axis ST’s I can mail you a piece of an Easton 2018 and you can check fitment with it before dropping the coin for donor arrows.

Similar threads

Featured Video

Latest Articles

- Aaron Davidson of Gunwerks

- TT#63 Dirk Durham’s Art of Elk Calling

- BIG Buck Stories with the Dirty Giants Podcast

- TT#62 Brian Barney Hunting Bulls without Calling

- Hoyt Alpha AX-2 SD Review

- Kuiu Kenai vs Outdoor Vitals Vario Hooded Jacket Review

- Hoyt RX-9 Ultra Review

- Hunting Vampire Bucks & Building an Optics Kit

- Darton Sequel ST2 35 Review

- TT#61 Gear and Skills for Success with Aron Snyder