I have a light weight hunting rifle I picked up on line , I didn’t think to check the threads , so when I got it I was surprised to find it had 1/2x28 , but it has a nice shoulder , I have looked at what some have done in the past and present , what are your thoughts , 24 1/2” barrel

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1/2x28 thread on 300wm

- Thread starter 68Hoyt

- Start date

jimh406

WKR

Some people have noted there is a minimum thread dimension recommended by some suppressor manufacturers for 30 cal. However, if you added a 5/8-24 adapter, I feel like that would increase the barrel strength at the end. I haven't tried it and don't have a 1/2-28 threaded 30 cal.

Adding a thread adaptor doesn't add metal onto the barrel at it's weakest point (the undercut). It just adds more weight, which I believe also increases shear.Some people have noted there is a minimum thread dimension recommended by some suppressor manufacturers for 30 cal. However, if you added a 5/8-24 adapter, I feel like that would increase the barrel strength at the end. I haven't tried it and don't have a 1/2-28 threaded 30 cal.

Attachments

Curious if that is factory threading. Are you wanting to shoot suppressed or just add a brake? TBAC recommends 9/16-24 as the minimum for .30 cal.I have a light weight hunting rifle I picked up on line , I didn’t think to check the threads , so when I got it I was surprised to find it had 1/2x28 , but it has a nice shoulder , I have looked at what some have done in the past and present , what are your thoughts , 24 1/2” barrel

Yea it is factory 1/2 x28 on a 300 wm , a cooper back country , has a nice shoulder , at one time tbac would do a break that they machined in house that threaded on and seated against the muzzle or muzzle and shoulder perfectly but now they don’t want to do this , sico dosent have a problem with 1/2x28 with their new can ,,,,,,, but I want to run a ultra 7

I bought a howa 300 wm that had 1/2x28 threads from the factory. Same as you in never crossed my mind to check that before I bought. So I called and emailed Legacy, they got back with me and gave me the name of a gunsmith in oregon who had brakes that fit. I called the gunsmith and he assured me he had did lots of them and never had a issue so I bought. It fit perfect and thru prob 50 shots there were no issues. I dont have the gun anymore but assume its all good.

DanM

FNG

- Joined

- Mar 27, 2024

- Messages

- 20

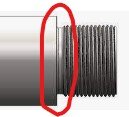

Good question and not meaning to hi-jack the original question: But those of us with thin factory barrels are interested to know the potential hazards with "too" small of threads. It seems 1/2"-28 seems to not leave much material between the thread root and the OD of the bore, not even taking into account the undercut at the shoulder and how it is accomplished. Without replacing the barrel - 3x+ investment versus threading - can a 0.660" OD 30 caliber barrel be threaded at all? Or should it?

TimeOnTarget

Lil-Rokslider

- Joined

- Jul 29, 2015

- Messages

- 179

I’ve got multiple rifles threaded 1/2x28 and then adapted to 5/8x24 due to the barrel profile. I just thought that was the standard when needed. Work was done by very competent gunsmiths.

No issues on any of my rifles.

No issues on any of my rifles.

swavescatter

Pain in the butt!

- Joined

- Apr 3, 2021

- Messages

- 1,609

Send it.

0.662" OD is the min. TBAC recommends for 9/16x24 which is the min. threading they recommend for .30 cal.Good question and not meaning to hi-jack the original question: But those of us with thin factory barrels are interested to know the potential hazards with "too" small of threads. It seems 1/2"-28 seems to not leave much material between the thread root and the OD of the bore, not even taking into account the undercut at the shoulder and how it is accomplished. Without replacing the barrel - 3x+ investment versus threading - can a 0.660" OD 30 caliber barrel be threaded at all? Or should it?

The biggest potential hazard in going too thin is if you accidentally drop your rifle or bang the end of the barrel on something, the end could shear off or bend at the weakest point (undercut).

If you bring up the subject with Bartlein or TBAC, they don't recommend going below 9/16x24 for any .30 cal. My guess is they determined through their own testing that accuracy starts to decline and becomes unacceptable below that threshold. The only way to know if it will have enough stiffness to keep the point of impact from shifting around and be acceptable for your needs is to test it out.

DanM

FNG

- Joined

- Mar 27, 2024

- Messages

- 20

Makes sense

jimh406

WKR

The only way to know is have them post why somewhere. There are several rifle companies that thread 1/2-28 on 30 cals and call them suppressor ready. And many other suppressor manufacturers that seem to be silent on what size is required for their suppressors. Again, I don't have a 1/2-28 threaded 30 cal.My guess is they determined through their own testing that accuracy starts to decline and becomes unacceptable below that threshold.

Should you believe the rifle manufacturer or one of two of the many suppressor manufacturers? Or, is the point to be as safe as possible, but in that case, shouldn't all calibers have the same requirement? For instance, I'm pretty sure a 7 mag or 7 PRC has more power and causes more deflection than a 7.62x39. Also, there is more leverage on a longer barrel/suppressor.

In any case, it would be nice how those two companies came up with that measure. Maybe they will post somewhere.

wind gypsy

"DADDY"

- Joined

- Dec 30, 2014

- Messages

- 12,274

id contemplate different alternatives if I were threading it but I would just use it as is if I were in your position.

rokslide.com

rokslide.com

1/2x28 Threaded 30 Cal Rifles - Suppressor Horror Stories

The internet seems to have two camps. People who run a suppressor on 1/2x28 threaded 30 cal rifles with no issues and people, including gunsmiths and manufacturers, who say it's a bad idea. I am only interested in two responses to this thread: Response 1.) "I run a suppressor on a (insert 30...

rokslide.com

rokslide.com

Feel free to contact them yourself, which is exactly what I did when I was trying to figure out which direction to take on threading a factory Tikka sporter barrel for a suppressor. Both companies were very helpful and gave more detailed answers than I was able to fully understand. I spoke with them both within the past year and didn't take notes or anything, but their recommendations on a path forward for my project were essentially the same. That carried a lot of weight with me, ymmv.The only way to know is have them post why somewhere. There are several rifle companies that thread 1/2-28 on 30 cals and call them suppressor ready. And many other suppressor manufacturers that seem to be silent on what size is required for their suppressors. Again, I don't have a 1/2-28 threaded 30 cal.

Should you believe the rifle manufacturer or one of two of the many suppressor manufacturers? Or, is the point to be as safe as possible, but in that case, shouldn't all calibers have the same requirement? For instance, I'm pretty sure a 7 mag or 7 PRC has more power and causes more deflection than a 7.62x39. Also, there is more leverage on a longer barrel/suppressor.

In any case, it would be nice how those two companies came up with that measure. Maybe they will post somewhere.

Here is a pretty interesting thread from a few years back. Opinions certainly vary. The last post in the thread caught my eye when I was searching and trying to read everything I could on the subject:

Muzzle break threading 300 win mag

Is 1/2x28 enough for a pencil barreled 300 win mag? My initial though is no but not 100% on it?

Similar threads

- Replies

- 3

- Views

- 153

Featured Video

Latest Articles

- TT#64 Josh Boyd Elk Hunting Strategies for Every Season

- Aaron Davidson of Gunwerks

- TT#63 Dirk Durham’s Art of Elk Calling

- BIG Buck Stories with the Dirty Giants Podcast

- TT#62 Brian Barney Hunting Bulls without Calling

- Hoyt Alpha AX-2 SD Review

- Kuiu Kenai vs Outdoor Vitals Vario Hooded Jacket Review

- Hoyt RX-9 Ultra Review

- Hunting Vampire Bucks & Building an Optics Kit

- Darton Sequel ST2 35 Review