Jared Lampton

WKR

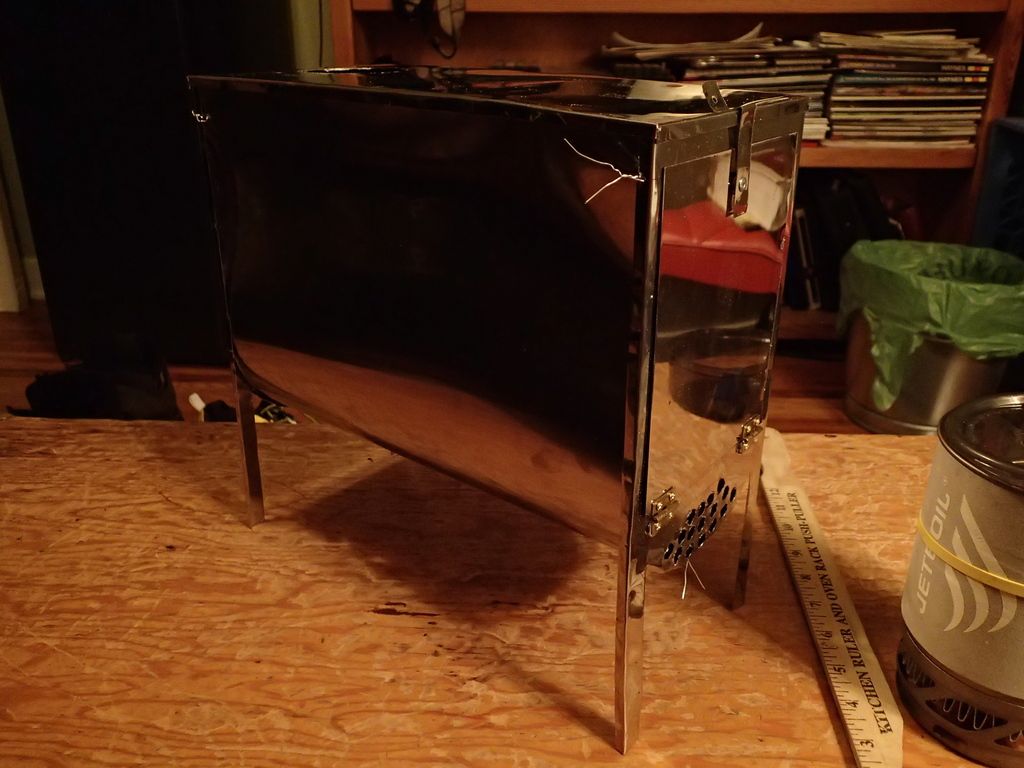

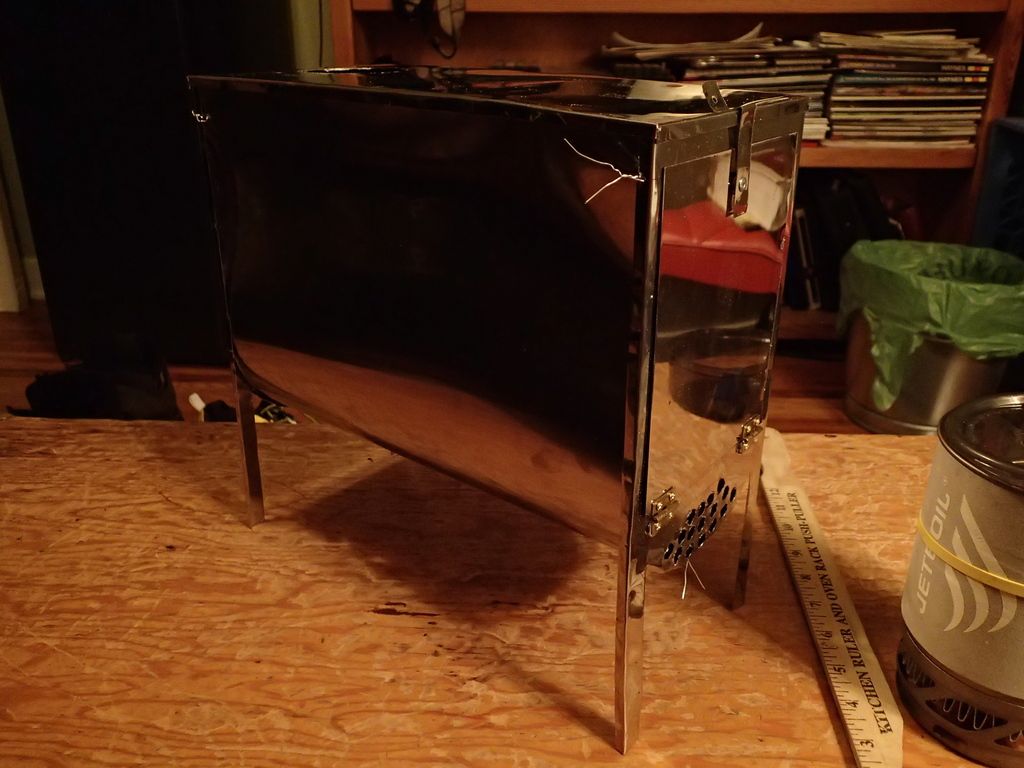

The other thread inspired me to build my own stove for my LBO but I didn't really want a cylinder or a box stove. I really liked the design of the HPG shepherd stove so I kind of copied that. I have zero experience using these lightweight stoves let alone building one but it seemed easy enough so I gave it a try. It's 11.5 inches long 8.5 inches deep and 5.5 inches wide. Weighs 1lb 9 oz including a 6 foot ti pipe. The stove body is a combination of titanium and SS. I've got about $200 into it. I can go more into the specifics if anyone is interested.

burn in

I've only burnt it once and it seemed to perform quite well. Definitely far from proven but it shows potential.

burn in

I've only burnt it once and it seemed to perform quite well. Definitely far from proven but it shows potential.