I have been a Product Design Engineer for 20 years, my role for the last 13 years has been in high strength consumer products, most of them polymer (with some diecast aluminum, fabricated steel, and wood designs too).

I am always tinkering with my guns, and am shocked at the materials polymer stocks are made of. We do a lot of PA6 Nylon with glass fill. We use 10%-50% depending on the application. I've never done a burn analysis on a stock, but most appear to be made from 10%-15% Nylon and a few that were glass filled Polypro (we do this on parts that need to be low cost).

We use mid-grade polymers for most parts (mostly because the market demands some recycled content). 10% GF nylon is about $1.50 per pound and 50% is about $2 per pound. Polymer prices vary but the price of 50% vs 10% as you change the grade of base PA6.

A Ruger American synthetic stock weighs 1.8 Lbs, most are a bit heavier. So if we call it 2lbs the difference between going low glass and ultra-high glass is about $1 cost (throw another 50% in there for the cost of tool maintenance and the multiple profit margins and I'd say the cost to the end consumer would be about $3). The only negatives to 50% glass filled nylon are appearance (you see all that glass on the surface unless you flash cool the tool) and it is a bit less impact resistant. To me the appearance of high glass nylon would look great on a hunting rifle, and besides you can hide that glass with a heavy texture if you want. The pros are it is multitudes stiffer, stronger, and much less likely to warp during the cooling phase (the reason a lot of barrels touch the stock).

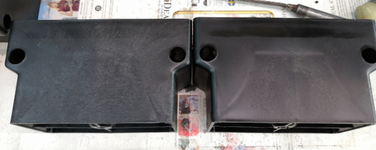

I had a 1.5lb 50% glass filled PA6 part once that the customer doubted was strong enough for the 350 Lbs load it was designed for. It was about the size of a rifle stock (it looked like a hollow banana sliced down the long axis). I made a video of me driving the front tire of my F150 over it and parking. It deflected about 1/4" under that load...

Maybe I missed it, but why have we never seen a high-glass Nylon synthetic stock??? Manufacturers could go 2 ways: they could make incredibly stiff stocks for $3 more to the customer or they could make ultralight stocks the weigh about 1Lb and cost the same as the standard flexible stock every manufacturer seems to sell.

Just my nerdy 2 cents....

I am always tinkering with my guns, and am shocked at the materials polymer stocks are made of. We do a lot of PA6 Nylon with glass fill. We use 10%-50% depending on the application. I've never done a burn analysis on a stock, but most appear to be made from 10%-15% Nylon and a few that were glass filled Polypro (we do this on parts that need to be low cost).

We use mid-grade polymers for most parts (mostly because the market demands some recycled content). 10% GF nylon is about $1.50 per pound and 50% is about $2 per pound. Polymer prices vary but the price of 50% vs 10% as you change the grade of base PA6.

A Ruger American synthetic stock weighs 1.8 Lbs, most are a bit heavier. So if we call it 2lbs the difference between going low glass and ultra-high glass is about $1 cost (throw another 50% in there for the cost of tool maintenance and the multiple profit margins and I'd say the cost to the end consumer would be about $3). The only negatives to 50% glass filled nylon are appearance (you see all that glass on the surface unless you flash cool the tool) and it is a bit less impact resistant. To me the appearance of high glass nylon would look great on a hunting rifle, and besides you can hide that glass with a heavy texture if you want. The pros are it is multitudes stiffer, stronger, and much less likely to warp during the cooling phase (the reason a lot of barrels touch the stock).

I had a 1.5lb 50% glass filled PA6 part once that the customer doubted was strong enough for the 350 Lbs load it was designed for. It was about the size of a rifle stock (it looked like a hollow banana sliced down the long axis). I made a video of me driving the front tire of my F150 over it and parking. It deflected about 1/4" under that load...

Maybe I missed it, but why have we never seen a high-glass Nylon synthetic stock??? Manufacturers could go 2 ways: they could make incredibly stiff stocks for $3 more to the customer or they could make ultralight stocks the weigh about 1Lb and cost the same as the standard flexible stock every manufacturer seems to sell.

Just my nerdy 2 cents....