Hi,

I am prepping some once fired Hornady brass for a Tikka T3X in 6.5 CM. I just FL resized using a Hornady custom die to bump the shoulder 0.002, and then checked them all through a Lyman headspace gauge. 11/30 brass processed are coming in just slightly too long, (at the neck, not HS), about 0.001 to 0.003 over spec.

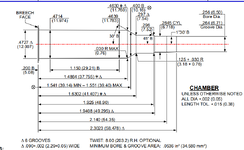

I have measured the chamber of the rifle at 2.9480, and am reloading to max COAL at 2.8250, so I have a jump to lands of 0.1230. I understand the value of trimming cases to all being uniform as it pertains to accuracy, but I am wondering if there any safety concerns reloading and shooting that brass without trimming it, since there is such a jump to lands. I can't imagine the case mouth being compressed in the lands and not expanding to allow the bullet to release, but want to hear the opinions of other with much more experience than myself. Are there other safety considerations of a slightly too long case neck?

I have a case trimmer on order and intend on trimming cases for uniformity as my ultimate goal in reloading is precision, but for the time being I do not have a trimmer and was hoping to continue my testing. Of course if it isn't safe, it's a no go until the trimmer arrives. Any insight is appreciated, thank you!

I am prepping some once fired Hornady brass for a Tikka T3X in 6.5 CM. I just FL resized using a Hornady custom die to bump the shoulder 0.002, and then checked them all through a Lyman headspace gauge. 11/30 brass processed are coming in just slightly too long, (at the neck, not HS), about 0.001 to 0.003 over spec.

I have measured the chamber of the rifle at 2.9480, and am reloading to max COAL at 2.8250, so I have a jump to lands of 0.1230. I understand the value of trimming cases to all being uniform as it pertains to accuracy, but I am wondering if there any safety concerns reloading and shooting that brass without trimming it, since there is such a jump to lands. I can't imagine the case mouth being compressed in the lands and not expanding to allow the bullet to release, but want to hear the opinions of other with much more experience than myself. Are there other safety considerations of a slightly too long case neck?

I have a case trimmer on order and intend on trimming cases for uniformity as my ultimate goal in reloading is precision, but for the time being I do not have a trimmer and was hoping to continue my testing. Of course if it isn't safe, it's a no go until the trimmer arrives. Any insight is appreciated, thank you!