sndmn11

"DADDY"

Im always looking- grin

I was thinking of trying something with Cru Wear- tho expensive.

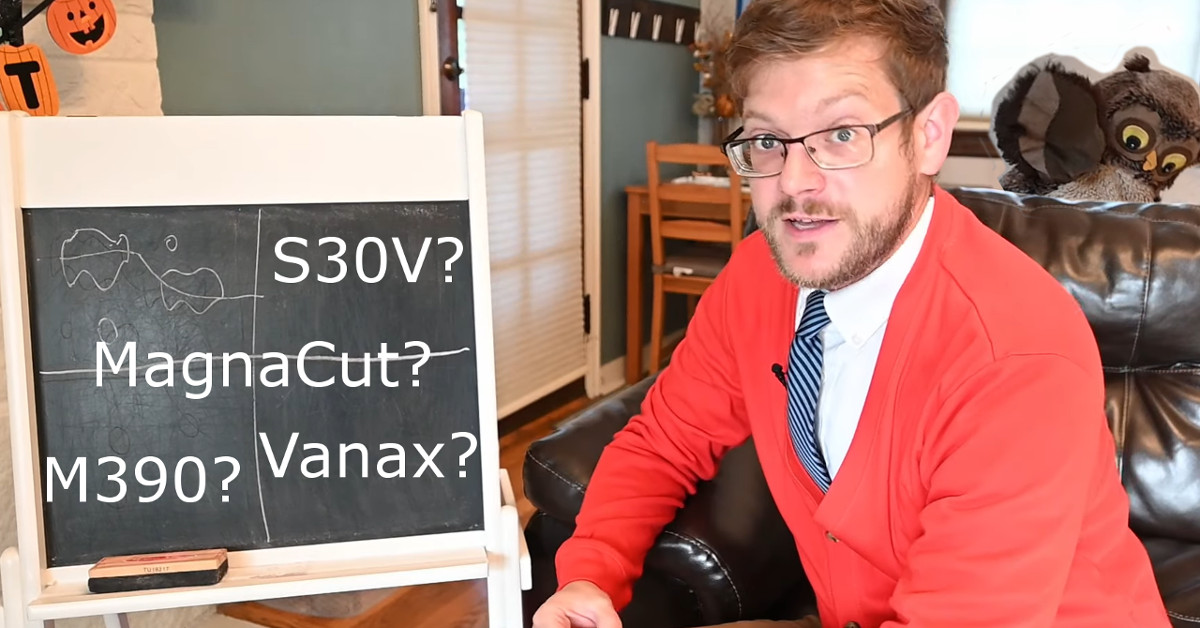

You’re a knife guy, what steels do you like in a processing knife?

M4 ish if I had only one.

There was a random M4 blade on the classifieds here that looked cool.

I've almost bought this a few times.

Temperance™ CPM® CRU-WEAR® - Spyderco, Inc.

Designed by company co-founder Sal Glesser, the Temperance was one of Spyderco’s earliest fixed blade models. Now this classic design is back as a limited-edition Sprint Run, showcasing a gray-colored fiberglass-reinforced-nylon (FRN) handle and a fu...

S90v is great if one is a slicer and not a pusher