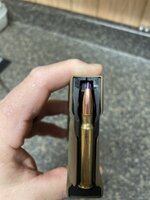

I'm putting together a .223 trainer based off the 700 footprint. My action is cut for a wyatts extended box (Bighorn SR3). I've been trying to figure out what my options are for the best/longest OAL. Wyatts has an internal box that goes 2.430, but I'd like to be closer to 2.50 if possible. I know I can go DBM and get there with an ACIS style mag. I've heard of pulling/modifying the spacer in the factory internal magazine but not sure if that's an option with the Wyatts (I can't find a factory mag box). My stocks inlet is for BDL floorplate but I can get it opened up to M5 if needed.

I'm leaning towards .223 AI chamber if that makes a difference. What other options are out there?

I'm leaning towards .223 AI chamber if that makes a difference. What other options are out there?