@Ryan Avery Said I should post this here as well as our social media pages...

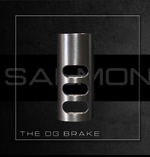

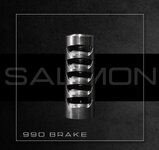

We will be doing a 9 part series with photos and brief descriptions on how we ended up with the designs that we currently use. What we have made first looks almost nothing like what we offer now. We figured it would be cool to showcase the evolution from a design, functionality, and machinability standpoint.

Here's the teaser photo... once we start releasing them on social media I will add each post here.

Ken

We will be doing a 9 part series with photos and brief descriptions on how we ended up with the designs that we currently use. What we have made first looks almost nothing like what we offer now. We figured it would be cool to showcase the evolution from a design, functionality, and machinability standpoint.

Here's the teaser photo... once we start releasing them on social media I will add each post here.

Ken