Years ago a won a Ruger American .243 at a banquet. Shot the gun maybe once and put it in the safe and forgot all about it. This year my daughter completed her hunters safety so I decided I needed to get her a rifle and the .243 seemed about right. I took the rifle out with the factory stock on it, and though it wasn't shooting sub 1/2 MOA, it shot extremely well with factory ammo.

Given that my daughter is only 8 the LOP on the factory stock is just far too long. I purchased a laminated Boyd's stock and cut the but down and did a little reshaping to make a good youth rifle. I did this same conversion on a 6.5 CM Kimber rifle for my son a couple years back. This rifle shoots the exact same sub MOA with both the factory stock as well as the modified Boyds stock. I have swapped them back and forth several times a year and never had any issues or differential in accuracy.

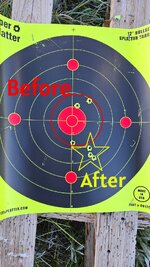

The Ruger however is shooting absolutely terrible in the new Boyd's stock. It went from about a 1" 3 shot group at 100 yards to nearly 4" groups. Same ammo, same shooter, relatively same weather conditions, same everything except the stock. I used the provided epoxy and bedded the lugs in the new Boyds per the instructions. There is no barrel contact on the new stock and everything seems to be free floating and tightened properly. I went ahead and grabbed 2 more rifles out of the safe and shot them to make sure the issue wasn't me. They both shot flawlessly so I feel like the new stock is truly the issue with the .243 rifle.

Looking for suggestions from you guys to see why the factory stock would shoot so much better than the new Boyd's and what I can try and tweak with to get the accuracy back.

Given that my daughter is only 8 the LOP on the factory stock is just far too long. I purchased a laminated Boyd's stock and cut the but down and did a little reshaping to make a good youth rifle. I did this same conversion on a 6.5 CM Kimber rifle for my son a couple years back. This rifle shoots the exact same sub MOA with both the factory stock as well as the modified Boyds stock. I have swapped them back and forth several times a year and never had any issues or differential in accuracy.

The Ruger however is shooting absolutely terrible in the new Boyd's stock. It went from about a 1" 3 shot group at 100 yards to nearly 4" groups. Same ammo, same shooter, relatively same weather conditions, same everything except the stock. I used the provided epoxy and bedded the lugs in the new Boyds per the instructions. There is no barrel contact on the new stock and everything seems to be free floating and tightened properly. I went ahead and grabbed 2 more rifles out of the safe and shot them to make sure the issue wasn't me. They both shot flawlessly so I feel like the new stock is truly the issue with the .243 rifle.

Looking for suggestions from you guys to see why the factory stock would shoot so much better than the new Boyd's and what I can try and tweak with to get the accuracy back.