Packmansion

WKR

- Joined

- Sep 24, 2022

- Messages

- 583

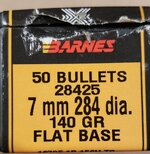

The load I am developing has a different max charge across multiple loading manuals by as much as 3.5 grains. It is H4350 with 168 TTSX. I have a Chrono and a 22" tikka 30-06 superlite. I loaded some up using the highest max from Hogdon

24" barrel data:

Hogdon 2897 fps and 59 grains

Hornady 2900 and 58.9

Nosler 2872 and 57.5

barnes 2825 and 55.5

I am curious why Barnes is so far off the rest of the pack, at 55.5 I got 2799 not to far off.

I hit 2910 fps with 57.5 grains. I got very mild ejector mark but its Federal Brass... I got an ejector mark on the first low charge shot as well. I am not getting any hard bolt lift. I plan to dial the load back to somewhere between 56.5 and 57 where I was getting right around 2850 which correcting for barrel length would match the load data velocity. I just wanted to share this and get people to chime in on what they would do and what they have seen.

24" barrel data:

Hogdon 2897 fps and 59 grains

Hornady 2900 and 58.9

Nosler 2872 and 57.5

barnes 2825 and 55.5

I am curious why Barnes is so far off the rest of the pack, at 55.5 I got 2799 not to far off.

I hit 2910 fps with 57.5 grains. I got very mild ejector mark but its Federal Brass... I got an ejector mark on the first low charge shot as well. I am not getting any hard bolt lift. I plan to dial the load back to somewhere between 56.5 and 57 where I was getting right around 2850 which correcting for barrel length would match the load data velocity. I just wanted to share this and get people to chime in on what they would do and what they have seen.