I'm in the process of building a 458 socom on a tikka action and have ran into a hiccup with getting large, flat nose bullets to feed into the action. What happens is the bolt pushes the cartridge forward, and the middle of the large, flat nose bullet jams into the action feed ramp and won't chamber. I'm going to order a different style of bullet to see if that helps, but in the meantime would appreciate some tips and tricks from others if they have had this issue or have any creative solutions.

Picture of 300gr RNFP loaded in MDT metal 6BR AICS mag

Magazine inserted into KRG Bravo with bolt to the rear

Pushing bolt forward and bullet about to jam on feed ramp

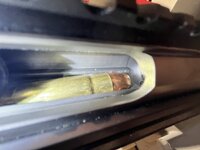

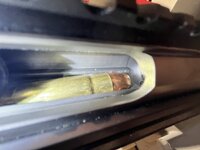

Bullet jammed on feed ramp

Tinkering a little last night trying to see how much of a "ramp" I need to get the nose of the bullet up enough, I cut a popsicle stick that goes from the back of the magazine follower and just flush with the front edge of the magazine body

Cartridge loaded on top of popsicle stick

magazine inserted and bolt to the rear

bullet at the feed ramp

bullet going up the feed ramp

The popsicle stick solution only works for one round.

Two ideas that i've come up with so far:

1) modify the magazine follower so that all the bullets in the magazine are angled upward and will feed onto the ramp, but i'm concerned raising the front of the cartridge too much will lower the rear, and the bolt will glide over the case head and not pick up a round

2) fabricate and attach a small ramp to the front of the magazine that doesn't move with the follower. it'd have to be tall enough to line up with the action feed ramp and short enough that it wouldn't interfere with the cartridges in the magazine.

Ideas and suggestions are appreciated.

Thanks all,

RH

Picture of 300gr RNFP loaded in MDT metal 6BR AICS mag

Magazine inserted into KRG Bravo with bolt to the rear

Pushing bolt forward and bullet about to jam on feed ramp

Bullet jammed on feed ramp

Tinkering a little last night trying to see how much of a "ramp" I need to get the nose of the bullet up enough, I cut a popsicle stick that goes from the back of the magazine follower and just flush with the front edge of the magazine body

Cartridge loaded on top of popsicle stick

magazine inserted and bolt to the rear

bullet at the feed ramp

bullet going up the feed ramp

The popsicle stick solution only works for one round.

Two ideas that i've come up with so far:

1) modify the magazine follower so that all the bullets in the magazine are angled upward and will feed onto the ramp, but i'm concerned raising the front of the cartridge too much will lower the rear, and the bolt will glide over the case head and not pick up a round

2) fabricate and attach a small ramp to the front of the magazine that doesn't move with the follower. it'd have to be tall enough to line up with the action feed ramp and short enough that it wouldn't interfere with the cartridges in the magazine.

Ideas and suggestions are appreciated.

Thanks all,

RH