Longleaf

Lil-Rokslider

I would try that load in a different pistol other than an XD and see if you have the same issue.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Hello,

I have a Springfield XDM9 9MM in which I am reloading the 9MM rounds. When I first started, I test-fired 50 reloads and they all worked without a jam. I continued to make about 1000 total. Went to the range today and every other round jammed.

Fire the first round - all good, the second round would not position correctly to be fired. The slide jammed hard shut to the point where even the range guy had difficulty unjamming it. This occurred with every second fire (about 5 attempts). The first bullet fired fine, second jammed. I tried factory loads and they worked fine, 100 rounds fired. I am 99% sure it’s the cycling that is jamming, not the firing, the second bullet jams before it's even fired.

My question is, what is my problem? Any tips on things to try?

At first, I was thinking it was not enough powder to cycle the chamber correctly. Although it does fire a little heavier than the factory rounds. So maybe it's too much powder. Since the die for powder is not adjustable and it worked fine with the first 50, I'm wondering if it's something else.

The next thing I was thinking of is the length. I did fool around with the dies to try to get a bullet feeder working, I wonder if I'm not crimping it down as far, I thought I measured but I'll have to go back over some and check.

The last thing, has anyone tried making a DIY clearing or bullet trap? As I try to fix these issues I want to test them without having to go to the range. Thinking of a 3-6" diameter few feet long metal conduit tube and filling it with water and/or sand to fire into. Or just buy one of these https://www.range-systems.com/product/guardian-compact-clearing-trap/ any thoughts?

Thanks in advance

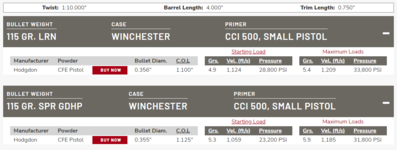

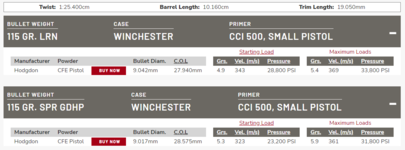

Make sure your overall length is in spec and very close to factory ball ammo or HP if that's what you're loading. If you suspect you're loading hotter than factory, back off to a mid-range load and try that. If you're that far off you're probably over pressure.Hello,

I have a Springfield XDM9 9MM in which I am reloading the 9MM rounds. When I first started, I test-fired 50 reloads and they all worked without a jam. I continued to make about 1000 total. Went to the range today and every other round jammed.

Fire the first round - all good, the second round would not position correctly to be fired. The slide jammed hard shut to the point where even the range guy had difficulty unjamming it. This occurred with every second fire (about 5 attempts). The first bullet fired fine, second jammed. I tried factory loads and they worked fine, 100 rounds fired. I am 99% sure it’s the cycling that is jamming, not the firing, the second bullet jams before it's even fired.

My question is, what is my problem? Any tips on things to try?

At first, I was thinking it was not enough powder to cycle the chamber correctly. Although it does fire a little heavier than the factory rounds. So maybe it's too much powder. Since the die for powder is not adjustable and it worked fine with the first 50, I'm wondering if it's something else.

The next thing I was thinking of is the length. I did fool around with the dies to try to get a bullet feeder working, I wonder if I'm not crimping it down as far, I thought I measured but I'll have to go back over some and check.

The last thing, has anyone tried making a DIY clearing or bullet trap? As I try to fix these issues I want to test them without having to go to the range. Thinking of a 3-6" diameter few feet long metal conduit tube and filling it with water and/or sand to fire into. Or just buy one of these https://www.range-systems.com/product/guardian-compact-clearing-trap/ any thoughts?

Thanks in advance

| Bullet diameter | 9.01 mm (0.355 in) |

| Land diameter | 8.82 mm (0.347 in) |

| Neck diameter | 9.65 mm (0.380 in) |

| Base diameter | 9.93 mm (0.391 in) |

| Rim diameter | 9.96 mm (0.392 in) |

| Rim thickness | 1.27 mm (0.050 in) |

| Case length | 19.15 mm (0.754 in) |

| Overall length | 29.69 mm (1.169 in) |

Plated bullets are oversized as well.LRN = Lead Round Nose. Not FMJ. Cast bullets are always slightly oversized.

Haha, yes, my mistake, like it says on the screen shot LRN. I was looking at FMJ while typing this and it must have just come out. You know how that happens sometimes.LRN = Lead Round Nose. Not FMJ. Cast bullets are always slightly oversized.