ERegs

FNG

- Joined

- Jun 20, 2020

- Messages

- 43

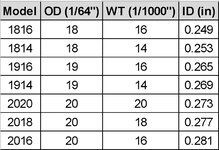

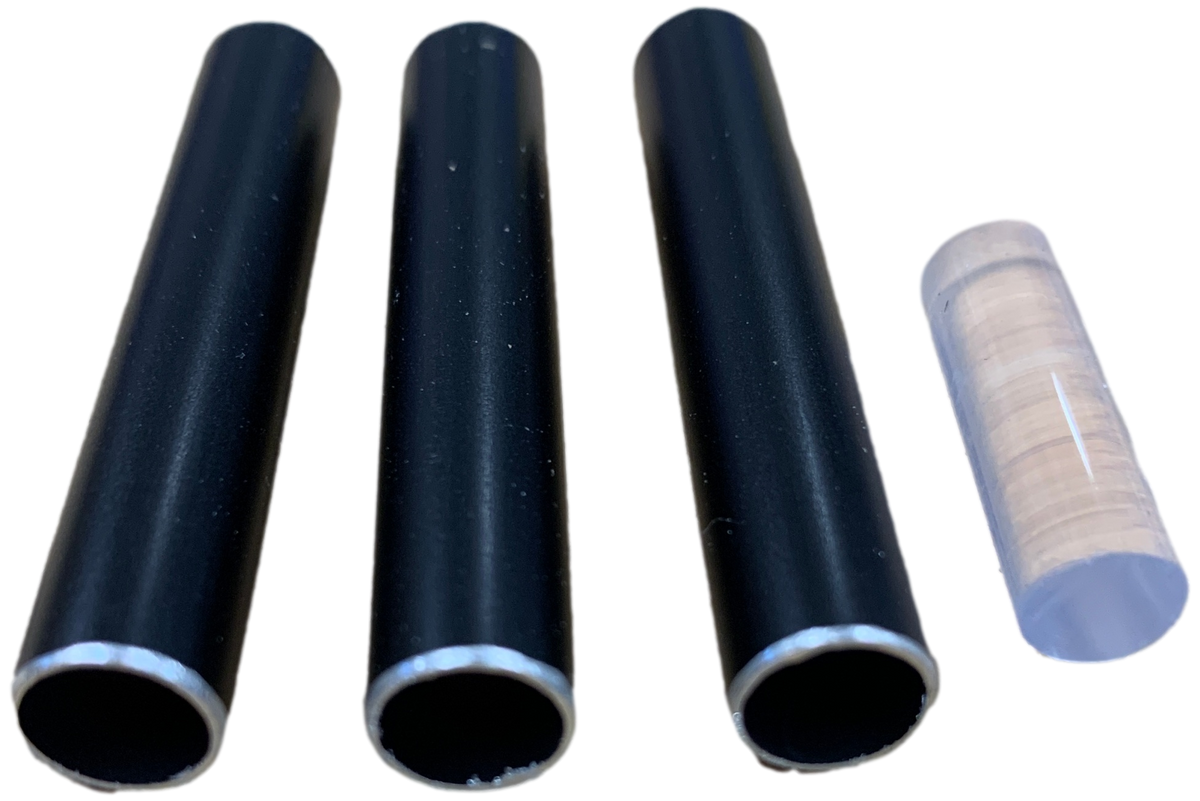

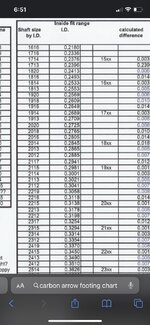

Anybody have any luck footing Easton axis shafts with say aluminum arrow. With shooting 3Ds if you miss and hit enough rocks and trees and such it mushrooms the arrow real easy. I know I know you not suppose to miss lol but were always trying to squeeze arrows through trees and shoot probably farther then we should. Just trying to make them a little more durable. I did find this bushing Easton makes too the may help but I don’t know. Any tips are appreciated thanks! https://eastonarchery.com/product/broadhead-alignment-rings-bar/