300-win-mag

FNG

Do dies go bad? Anyone have experience with bad dies?

Last edited:

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

only if you let them rust. there is nothing to go bad but the expander or the pin that punches out the primer.

on occasion a die can be too long and you will need to shave the shell holder down a few thousands.

what's the problem?

Could be caused by dirty brass. If you don't tumble your brass before resizing, wipe them real good with a clean cloth to remove as much dust, dirt, or grit that you can. If they are RCBS dies, send the sizer back, they will polish it out and return it to you in about a week, no charge. I have done it at least twice. I can't speak for other die companies, you could try calling them.

I doubt you could even feel it if you scraped it with your fingernail.

hard carbon on the brass caused the scratch in the die. and the carbon is still in there if it is causing cases to be scratched. midway will get you a single new hornady FL die if you dont want to send that one in to hornady.

do you have a bushing die? if not now is the time to switch to a bushing die.

it has been years and years since i tumbled brass. i find tumbling a pain.

goof job!

some mildly abrasive bore paste on a patch might help, too.

Small brass bits, dust and other fine foreign matter can cause case galling in sizing dies and neck bushings. Poor machining or lack of polishing can also create this problem.

To combat this issue I get some wooden dowel stock, some electrical tape and some 1000 grit and 2000 grit wet/dry sand paper. First I cut a desired length of dowel then make a cut on one end with a thin blade hack saw. Then slide in a cut piece of 1000 grit sandpaper and wrap it around the dowel. Then you can chuck it all in a drill and get to polishing. I start with 1000 grit then on to the 2000 grit. The electrical tape can be used to get a desired diameter before adding the sandpaper. I also use bore brushes with and without 000 steel wool and 0000 steel wool to get the desired result. This has worked great for me, it leaves the insides of bushings and dies looking like a mirror... and no scratched cases!View attachment 253071View attachment 253072View attachment 253073

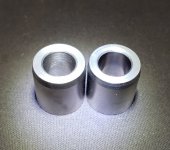

No problem, glad to help. It can definitely breathe new life into old neglected dies as well. Here is a bushing I have not polished next to one that is.Exactly where I'm headed now- thanks for the visual aids! Much appreciated

No problem, glad to help. It can definitely breathe new life into old neglected dies as well. Here is a bushing I have not polished next to one that is.

Edit: Also make sure to thoroughly clean the die/bushing after polishing and before running any brass through them.

View attachment 253094

Excellent! Good to hear.Wanted to bump this and follow up. I did exactly what Muley Buck described, and had the same results shown on my .308 dies that had previously been scarring brass. In fact, the results were so good I did it to all my sizing dies. The interior of the die bodies are now smooth enough to reflect images like a mirror. Just resized a bunch of casings and it's impossible to tell they've ever seen a die. Total materials were about $15 from Home Depot. Thanks again for the hot tip!