I'm fairly new to reloading, but having struggles with inconsistent loads with 223 77TMK.

My components are:

My reloading equipment:

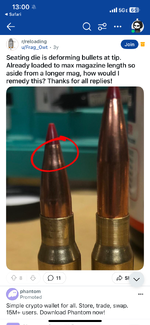

During the entire seating processes I was getting inconsistent depths. I checked over and over to make sure my die was set correctly and locked down tight. Sometimes I would be off by 0.02" and other times by as much as 0.09". In the end I would adjust the micro dial and get it (close) to the correct COAL of 2.26". My bullets also had ring marks on the top portion of the bullet. I tried to listen and feel for powder crunch, but perhaps because of my inexperience I couldn't really hear or feel for it.

Today I went and shot about 20 of these loaded rounds in my AR-15. Measuring with a Caldwell chronograph my ES was 136 and SD was 42.

I'm wondering, is it possible that I have too much compression with this load? 22gr is the max from Sierra's load data for 8208 XBR. Looking through Rokslide it appears others are using even more powder without issues though.

Any other recommendations what I could be doing incorrectly?

I greatly appreciate the help.

My components are:

- Sierra TMK 77gr projectile

- New Starline 223 brass

- IMR 8208 XBR powder

- CCI 450 primers

- COAL = 2.26"

- Powder = 22gr

My reloading equipment:

- RCBS Rock Chucker Supreme

- Forster Full Length Sizing Die

- Forster Ultra Micrometer Seater Die

- Forster Funnel with Long Drop Tube

- Lyman Case Prep Tool

- Harbor Freight Digital Calibers (tested against precision blocks)

- RCBS 505 Scale and AND Digital Scale (both tested w/ precision weights)

During the entire seating processes I was getting inconsistent depths. I checked over and over to make sure my die was set correctly and locked down tight. Sometimes I would be off by 0.02" and other times by as much as 0.09". In the end I would adjust the micro dial and get it (close) to the correct COAL of 2.26". My bullets also had ring marks on the top portion of the bullet. I tried to listen and feel for powder crunch, but perhaps because of my inexperience I couldn't really hear or feel for it.

Today I went and shot about 20 of these loaded rounds in my AR-15. Measuring with a Caldwell chronograph my ES was 136 and SD was 42.

I'm wondering, is it possible that I have too much compression with this load? 22gr is the max from Sierra's load data for 8208 XBR. Looking through Rokslide it appears others are using even more powder without issues though.

Any other recommendations what I could be doing incorrectly?

I greatly appreciate the help.