Clucknmoan

FNG

- Joined

- Sep 30, 2018

- Messages

- 30

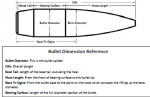

Your seating stem actually contacts the bullet forward of the ogive, or at least all of them I’ve measured. Some seating stems just don’t work well with certain types of bullets because of their shape. It’s not that they touch or bottom out at the bullet tip. The seating stem can actually bite into or grab the bullet on your upswing, moving it out. It’s not much and I’m not saying that’s what’s happening, but it can especially with light tension.

Can you see a ring or indent on your bullet between the ogive and the tip after they are seated? How many times have you fired this brass?

Can you see a ring or indent on your bullet between the ogive and the tip after they are seated? How many times have you fired this brass?