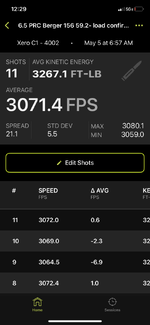

Alright all. I thought I had a really good load with 6.5 PRC, Berger 156, ADG, gm210m, and N565 @59.2.

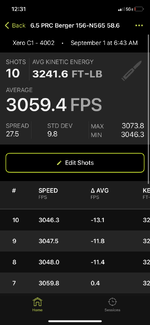

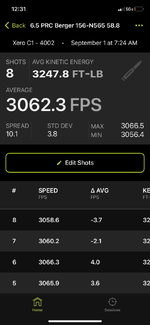

With virgin brass I had avg velocity of 3072 and .8 MOA on a 10 shot group (see first picture and second picture ). After FL resizing and trying out my new Mark 2 db annealer I loaded up some more. Note on FL sizing I didn’t bump shoulder yet because the case was still fitting into chamber.

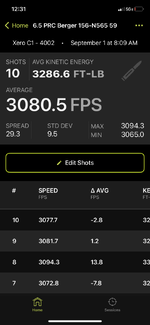

Round 2 at the range. I noticed couple loads the bolt was a little stiff on closing. On some loads I noticed stiff bolt lift and ejector swipe on case heads. Put my chrono (Garmin) on and was recording avg 3100fps (third picture). Why did I have the sudden increase in pressure and velocity? ***barrel has already sped up and had to back it down from 59.9 to 59.2 to get back to 3070 fps. Was it because of annealing or should have I bumped the shoulder a little? Virgin brass had a measurement of 1.645 BTS, 1x fired 1.650 BTS, and 2x fired 1.653.

Round 3 at range. Decided to back off the charge as I was into pressure for some reason. Loaded up 3 loads 10 shots each: 58.6, 58.8, and 59. The 10 shot groups are pictured in sequence below. Not really sure how to read these groups. It looks like 58.8 has vertical dispersion which I believe we want to stay away from. Which one should I further evaluate or should I go back to 59.2 and bump shoulder down to 1.648?

With virgin brass I had avg velocity of 3072 and .8 MOA on a 10 shot group (see first picture and second picture ). After FL resizing and trying out my new Mark 2 db annealer I loaded up some more. Note on FL sizing I didn’t bump shoulder yet because the case was still fitting into chamber.

Round 2 at the range. I noticed couple loads the bolt was a little stiff on closing. On some loads I noticed stiff bolt lift and ejector swipe on case heads. Put my chrono (Garmin) on and was recording avg 3100fps (third picture). Why did I have the sudden increase in pressure and velocity? ***barrel has already sped up and had to back it down from 59.9 to 59.2 to get back to 3070 fps. Was it because of annealing or should have I bumped the shoulder a little? Virgin brass had a measurement of 1.645 BTS, 1x fired 1.650 BTS, and 2x fired 1.653.

Round 3 at range. Decided to back off the charge as I was into pressure for some reason. Loaded up 3 loads 10 shots each: 58.6, 58.8, and 59. The 10 shot groups are pictured in sequence below. Not really sure how to read these groups. It looks like 58.8 has vertical dispersion which I believe we want to stay away from. Which one should I further evaluate or should I go back to 59.2 and bump shoulder down to 1.648?

Attachments

-

A12690B0-AFF2-4EAA-9A87-826DB473F6D8.jpeg198.5 KB · Views: 34

A12690B0-AFF2-4EAA-9A87-826DB473F6D8.jpeg198.5 KB · Views: 34 -

F8280C75-F026-48B8-873B-C979AE8F1F61.png186.3 KB · Views: 33

F8280C75-F026-48B8-873B-C979AE8F1F61.png186.3 KB · Views: 33 -

D0EA3F39-6DDB-44D6-86C4-AE547463E82D.png186.5 KB · Views: 35

D0EA3F39-6DDB-44D6-86C4-AE547463E82D.png186.5 KB · Views: 35 -

F9A9A268-01EC-4236-AB20-815BDDA94CFC.jpeg139.5 KB · Views: 35

F9A9A268-01EC-4236-AB20-815BDDA94CFC.jpeg139.5 KB · Views: 35 -

4FAA9A61-17A4-4B3D-86B3-10B231A26216.png197.1 KB · Views: 34

4FAA9A61-17A4-4B3D-86B3-10B231A26216.png197.1 KB · Views: 34 -

0A6536CB-BCBB-462C-B504-B1B8E37C07E5.png197 KB · Views: 25

0A6536CB-BCBB-462C-B504-B1B8E37C07E5.png197 KB · Views: 25 -

9F3BCC35-493D-4E91-98FD-C9398BDEBA5D.png200 KB · Views: 32

9F3BCC35-493D-4E91-98FD-C9398BDEBA5D.png200 KB · Views: 32