Badger 5

Lil-Rokslider

- Joined

- Feb 25, 2019

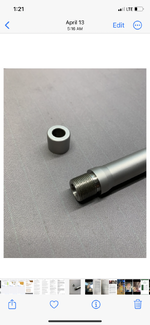

I am going to run a suppressor on my Tikka T3 Lite in 6.5CM with a 20 inch barrel. I got the barrel threaded by a local gunsmith in 5/8x24. He told me the shoulder would be smaller, but he wouldn’t have a problem running that thread size on my gun. Cool, the professional thinks 5/8x24 will work well.

I just got the gun back and thought “wow, that shoulder is tiny!”

I am no gunsmith, but this shoulder seems very small…would you be comfortable running these threads for a suppressor, or would you go back and get this done in 1/2x28?

My otter creek Hydrogen S got out of jail yesterday, very excited.

I just got the gun back and thought “wow, that shoulder is tiny!”

I am no gunsmith, but this shoulder seems very small…would you be comfortable running these threads for a suppressor, or would you go back and get this done in 1/2x28?

My otter creek Hydrogen S got out of jail yesterday, very excited.