The Rok Blog is the place to connect with some of the top backcountry gear manufacturers. Kurt Racicot of Stone Glacier Ultralight Backpacks sent me a great blog post on the physics of pack load. Understanding the concepts presented here will help you get the most out of your ultralight backpack. Take it away Kurt…

“While there are different theories on loading a pack, they all have one constant in common, the forces of gravity. By exploring the math, we can minimize the effects of gravity on the pack-out out regardless of the pack design you use.

Two of the major forces acting on our body under a loaded pack are the actual weight of the load and the leverage that load exerts on our body. While we cannot change the actual weight of the load, we can manage how much leverage that weight creates. Generally speaking, this is felt as leverage pulling us back, causing us to lean forward and engage our core to maintain balance. This added force can be as high as 40% of the total load weight on a poorly loaded pack, even more on a pack frame with short or no load lifters. This extra leverage also makes the load more unstable, requires more effort to remain balanced and in control. In technical country where every step counts, or while on crampons, it can also add an unneeded degree of risk.

To put an exact number to this additional force, I built a jig to test and understand the mechanical advantage. The jig simulates a 25” tall pack frame with a base 12” wide by 11” deep, the approximate size of many 6000 cubic bags.

To simulate the fulcrum created at our lower back with a loaded pack, the jig pivots at the hipbelt area and has a scale attached to the load lifter to record the force. There are six sand bags with a combined weight of 76 pounds. The first pic simulates loading the meat the full dimension of the bag bottom. The second simulates loading the meat in a shelf and compressing it to the frame.

Simulation #1 generated 31.87 pounds of force, Simulation #2 generates only 14.21 pounds. So with 76 pounds of meat, an extra 17.6 pounds of force is created on your body simply by how the pack is loaded. Loading the pack vertically and minimizing the horizontal distance between the load CG (center of gravity) and our body CG is the key. This also demonstrates one of the major functions of a load lifter. As the frame height and load lifter height decreases, the mechanical advantage to offset the leverage of the load also decreases. Based on this simulation, a 25” load lifter height can provide 25% more leverage than a 20” frame. This is one of the differences between what some call a “functional load lifter”, and a “load stabilizer.”

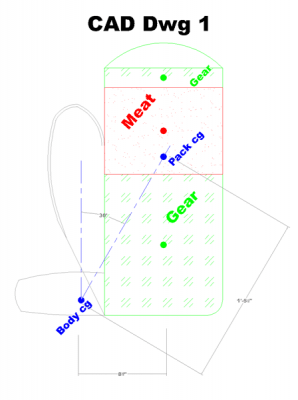

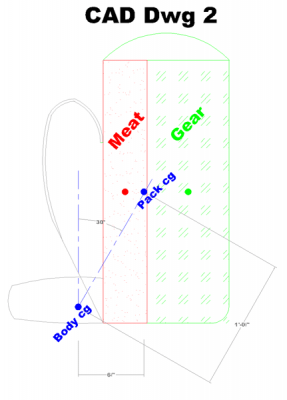

Minimizing this extra force can also be accomplished by loading the meat higher on frame, as shown in CAD drawing #1 below. I calculated that when loaded with a sheep/mule deer size animal and camp, approximately 70% of the weight (meat) uses 35% of my cubic inches. Based on this, both 6000 cubic-inch pack drawings below are drawn to scale to represent the needed location of gear and meat to minimize the angle and horizontal distance between our body CG and the loaded pack’s CG. Each colored dot represents the CG of that portion of the load, the Blue dots represent the combined and true CG of the entire loaded pack.

CAD drawing #1 shows meat placement in a standard pack configuration. By elevating the meat on the frame, we reduce the angle between the body CG and pack CG (30 degrees in this drawing.) The closer we come to aligning the body CG and the pack CG vertically, the more we reduce the effects of felt leverage, the less you have to lean forward to compensate.

Cad Drawing #2 shows how a pack would be loaded in the shelf/sling configuration to accomplish the same angle. While both are good options, the load shelf/sling configuration in drawing #2 moves the pack CG 30% closer to the body CG in comparison to the standard pack configuration even when the meat load is elevated. Proportionally, the load shelf will equate to a reduction of leverage compared drawing #1 in this example. While there are many more forces and vectors at work in these examples, this simplistic view shows the importance of load location.

Conclusion:

Regardless of which option works for you, compression is neccessary to reduce meat migration. If the load does not stay in place and shifts to the bottom of your pack, the effort to pack the same amount of weight has increased substantially. With load shift also comes loss of stability.

Additionally, a major point is placement of horns/skulls. When adding very dense loads, especially sheep horns or any skull with cape, loading at the top (like under the lid) of the pack, as close to the frame and back as possible will minimize any felt leverage. The general rule I use is to load gear diagonally lightest to heaviest, from the bottom outside of the bag to the top of the frame while keeping the heavier items as close to the pack frame as possible.

Whether a three-hour or three-day pack out, the extra force created with a poorly loaded pack increases effort required drastically. An ultralight pack’s weight advantage is not realized if not loaded properly. Understanding these principles will help make your pack as comfortable, stable, and safe as possible. Best of luck this fall.”

thanks a lot to kurt for showing us the research that his company is trying to make a pack that is both lightweight and durable for us guys that appreciate quality and thanks to robby for his blog

you’re welcome Shawn. When Kurt sent me that info, I just knew you all would like it. It’s been great to see the response. I just happen to know that Kurt is working on round 2, so stay tuned.

I wanted to add some clarification to what Kurt said about “load lifters” and “load stabilizers”.

Load lifters don’t actually lift any of the load off of your back, their purpose is to lift the shoulder straps off of the top of your shoulders which then transfers all of the weight of your pack onto the waist belt so that is it carried on your hips and not on your shoulders. The force exerted by the shoulder strap is now pushing horizontally from your chest towards the pack rather than vertically/down onto your shoulders. You may need to loosen your shoulder straps a little bit in order for the load lifters to lift them off of your shoulders. Also, load lifters can only lift the shoulder strap if their attachment point to the frame is ABOVE your shoulders; if they are not above your shoulders they are non-functional load lifters, functional load lifters are always above the shoulders. If they are not above the shoulders they will only act as load stabilizers.

Load stabilizers are intended to pull the pack body, and its weight, closer to your back which brings the packs center of gravity closer to your body’s center of gravity; they also help to minimize any sway the pack bag may have when you are moving. This is often done by flexing the frame/suspension at the shoulders to bring the weight closer to your back. Load stabilizers are normally found at shoulder height but are also often found at the hips. Pulling on your load lifters can do this too if you don’t loosen your shoulder straps or continue pulling on them after they have lifted the shoulder straps off of your shoulders.

Some pack/suspension designs use one set of straps to do both functions and others use multiple sets of straps to do it.

Comments are closed.