TurboSportTSi

FNG

Hi All,

I've been working up loads for a new rifle and am having a heck of a time. At this point, I don't know where to go next and am looking for advice. With components being scarce, I would like to avoid as much shot-in-the-dark testing as I can.

Rifle: Christensen Arms Traverse w/ 24" cf barrel. Break-in completed per mfg instructions - roughly 150rds on the barrel now. I bought this rifle to "easy button" load dev, since it's somewhat high end for an off the shelf rig. It is proving to be the worst shooting rifle I've ever owned! I can *barely* get ~1' groups, so I can't really send it back for a rebarrel...

Scope: NF NXS 2.5-10x42 in Talley UL mounts (2-piece mounts are not my favorite, but had trouble finding mounts low enough)

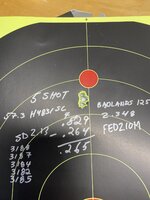

Bullet: 124 gr Hammer Hunter

Brass: Nosler factory seconds, pared down & weight sorted to remove defects and significant outliers (all within ~2.5% case weight). 1x fired & annealed. FL sized, 2 thou neck tension, 2 thou shoulder bump.

Shooter: Capable of 1/2 - 3/4 MOA consistently with my semi-custom 6.5 CM & handloads. Have shot slightly smaller groups, but not with any regularity - UNK if that is rifle-related or not (budget build).

Using Hammer Hunter 124 gr bullets and would like to stick with them if possible. This rifle will be for hunting use only. I used to work up loads for various bullets & powders for different purposes and it became a PITA so I am keeping it simple with this rig. I went with these bullets partly because they are very expensive and thus have no availability issues, which is perfect for a hunting rifle...and partly because I kept reading that load workups were so easy because they are so consistent and insensitive to seating depth.

I have tried H1000 with pretty dismal results, then read that Hammers typically work best with a faster powder due to the design of their bearing surfaces, so I tried some Superformance that I had on hand, with equally dismal results. I'm having trouble interpreting the data and see nothing that warrants further investigation. I have nothing in between, in terms of burn rate and I can't just go out and buy a pound of RL23 or similar.

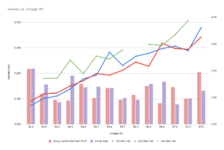

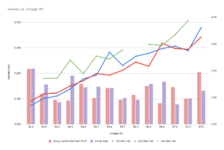

I have an optical chrony that has proved to be a pain in the rear and so I generally don't use it, so I have no velocity data for the H1000 load dev, but I wised up and tried it again for the Superformance dev and it worked fairly well. I usually use the OCW method, focusing on location of group centers relative to POA and not on group size. The trouble is, I can't discount group size completely, and the velocity nodes don't coincide at all with consistent group size and deviation from POA.

H1000 resulted in wild groups (like 2+ inches), then one random 5-shot group that had 4 shots touching, with one flyer about a half inch away. Moving on...

Superformance never really seemed to hit a velocity node but had multiple groups at around 1". Trying to conserve components, I only shot 2 strings, round robin style, before calling it quits. After graphing the data, I went back to the range later that day to shoot the 3rd string, which resulted in much higher velocity, but still reinforced the general velocity trend, save for a few chrony errors as light was fading. Could be that this kind of variation due to temp means that this powder is not for me.

My analysis indicates that 55.4gr is likely the center of a reasonably stable node and the 1st shot at that charge weight was a fluke. Both the second and third strings indicate a node there. The trouble is, the 55.7 & 56.0 groups were fairly consistent and make me want to split the difference between those two and test seating depth, but the velocity seems to be increasing steadily at that point.

What would you do? Any advice?

I've been working up loads for a new rifle and am having a heck of a time. At this point, I don't know where to go next and am looking for advice. With components being scarce, I would like to avoid as much shot-in-the-dark testing as I can.

Rifle: Christensen Arms Traverse w/ 24" cf barrel. Break-in completed per mfg instructions - roughly 150rds on the barrel now. I bought this rifle to "easy button" load dev, since it's somewhat high end for an off the shelf rig. It is proving to be the worst shooting rifle I've ever owned! I can *barely* get ~1' groups, so I can't really send it back for a rebarrel...

Scope: NF NXS 2.5-10x42 in Talley UL mounts (2-piece mounts are not my favorite, but had trouble finding mounts low enough)

Bullet: 124 gr Hammer Hunter

Brass: Nosler factory seconds, pared down & weight sorted to remove defects and significant outliers (all within ~2.5% case weight). 1x fired & annealed. FL sized, 2 thou neck tension, 2 thou shoulder bump.

Shooter: Capable of 1/2 - 3/4 MOA consistently with my semi-custom 6.5 CM & handloads. Have shot slightly smaller groups, but not with any regularity - UNK if that is rifle-related or not (budget build).

Using Hammer Hunter 124 gr bullets and would like to stick with them if possible. This rifle will be for hunting use only. I used to work up loads for various bullets & powders for different purposes and it became a PITA so I am keeping it simple with this rig. I went with these bullets partly because they are very expensive and thus have no availability issues, which is perfect for a hunting rifle...and partly because I kept reading that load workups were so easy because they are so consistent and insensitive to seating depth.

I have tried H1000 with pretty dismal results, then read that Hammers typically work best with a faster powder due to the design of their bearing surfaces, so I tried some Superformance that I had on hand, with equally dismal results. I'm having trouble interpreting the data and see nothing that warrants further investigation. I have nothing in between, in terms of burn rate and I can't just go out and buy a pound of RL23 or similar.

I have an optical chrony that has proved to be a pain in the rear and so I generally don't use it, so I have no velocity data for the H1000 load dev, but I wised up and tried it again for the Superformance dev and it worked fairly well. I usually use the OCW method, focusing on location of group centers relative to POA and not on group size. The trouble is, I can't discount group size completely, and the velocity nodes don't coincide at all with consistent group size and deviation from POA.

H1000 resulted in wild groups (like 2+ inches), then one random 5-shot group that had 4 shots touching, with one flyer about a half inch away. Moving on...

Superformance never really seemed to hit a velocity node but had multiple groups at around 1". Trying to conserve components, I only shot 2 strings, round robin style, before calling it quits. After graphing the data, I went back to the range later that day to shoot the 3rd string, which resulted in much higher velocity, but still reinforced the general velocity trend, save for a few chrony errors as light was fading. Could be that this kind of variation due to temp means that this powder is not for me.

My analysis indicates that 55.4gr is likely the center of a reasonably stable node and the 1st shot at that charge weight was a fluke. Both the second and third strings indicate a node there. The trouble is, the 55.7 & 56.0 groups were fairly consistent and make me want to split the difference between those two and test seating depth, but the velocity seems to be increasing steadily at that point.

What would you do? Any advice?