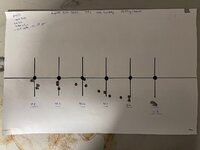

Looking to get some opinions on my OCW results. This is the first time trying this method shooting round robin 3 shot groups. Based off my limited knowledge it appears the lower charges seem to be the most forgiving but of course the tightest group is at max load (I know this test is not about group size).

No signs of pressure at max tested load.

Thanks for any input.

No signs of pressure at max tested load.

Thanks for any input.