I am starting to second guess everything, so throwing this out here for some (hopefully) insight as to highest probability paths first.

Goal: A mono-metal based 300WM load that can be used out to 1000y for deer sized game. (Note I personally would NEVER take that shot, as I don't have the skills, but this gun may be used by some folks that could, so I want a load that could do it)

Setup: Tikka 300WM, stock bottom metal, 22" CarbonSix Feather barrel (installed by CarbonSix).

Barrel Break-In:

The Barrel is a .5 MOA guarantee, so the fact that I am getting +1MOA (and I do have skills enough to shoot sub-moa), I am attributing it to the load.

At this point, I reached out to Gene at CarbonSix, and he suggested I go a heavier projectile with the 1:9, that the 175 might be too light. He also suggested I reach out to Jake at Unknown Munitions, as they develop a lot of loads for "shorter" C6 barrels . I did, and Jake confirmed that a 190 LRX would likely be a better projectile choice. I also reached out to Steve at Hammer to get his input about the 181g, and he said they had a good load worked up for 300WM with that (but that it was long bullet, so take that into consideration). Jake at UM also confirmed that the 181HH would be a bullet that could be that 1000y, should the need arise.

Steve said the 300WM 181g load they have had best success with was ADG, RL23 78.0, CCI 250, COAL 3.60. But told me that I should start at 72.0 and and do a pressure ladder.

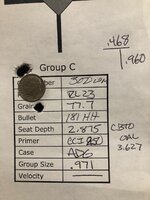

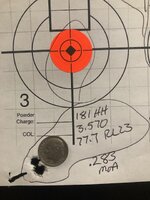

So I did that. 72.0, 73.0, ..., 79.0. I hit pressure at 79.0 (blew a primer, and hard bolt lift). Note that the velocity plot was almost linear for those (no node I could see). No hard lift or anything on anything up to that. So... I loaded up 9 ADG (unfired), 78.0 RL23, CCI 250, 181g HH, COAL 3.60 (have to single feed because of the Tikka Mag length).

Shot today and not any better results: First set of 3 POA was 2. 1st projectile off target high. ES for group was 7. 2nd group of 3 was at 5, 1&2 were right next to each other, 3 was low. ES 7. 3d group of 3 at 4. ES 20.

So as you can tell, not even close.

My next plan is to load up 3each @ 77.0, 76.0. 75.5 and see if there is better grouping. If they don't work, I may try another powder. There are just so many variables, and my experience level on this is such that I don't have "fallback" "these are things that seem to always work well together (or vice versa, they seldom work together). Any input in appreciated.

Goal: A mono-metal based 300WM load that can be used out to 1000y for deer sized game. (Note I personally would NEVER take that shot, as I don't have the skills, but this gun may be used by some folks that could, so I want a load that could do it)

Setup: Tikka 300WM, stock bottom metal, 22" CarbonSix Feather barrel (installed by CarbonSix).

Barrel Break-In:

- I followed the shoot 1, clean, shoot another, clean for first 10. Then Shot 5 more and did a clean. All with Hornady Interlocks (just to put copper down the barrel)

- I then shot a ladder of 175g LRX (as this was the bullet I wanted to load for). Settled on 75.0 Ramshot Hunter

- Shot 18 of that and was not happy with the groups +1 MOA on all

- I loaded some 175 with RL22 and tried a few along with the RH loads (12 total) and even did 6 H4350 on 166g HH that I had laying around just to "see what would happen" - 1 group of the HH was the only thing under an MOA

The Barrel is a .5 MOA guarantee, so the fact that I am getting +1MOA (and I do have skills enough to shoot sub-moa), I am attributing it to the load.

At this point, I reached out to Gene at CarbonSix, and he suggested I go a heavier projectile with the 1:9, that the 175 might be too light. He also suggested I reach out to Jake at Unknown Munitions, as they develop a lot of loads for "shorter" C6 barrels . I did, and Jake confirmed that a 190 LRX would likely be a better projectile choice. I also reached out to Steve at Hammer to get his input about the 181g, and he said they had a good load worked up for 300WM with that (but that it was long bullet, so take that into consideration). Jake at UM also confirmed that the 181HH would be a bullet that could be that 1000y, should the need arise.

Steve said the 300WM 181g load they have had best success with was ADG, RL23 78.0, CCI 250, COAL 3.60. But told me that I should start at 72.0 and and do a pressure ladder.

So I did that. 72.0, 73.0, ..., 79.0. I hit pressure at 79.0 (blew a primer, and hard bolt lift). Note that the velocity plot was almost linear for those (no node I could see). No hard lift or anything on anything up to that. So... I loaded up 9 ADG (unfired), 78.0 RL23, CCI 250, 181g HH, COAL 3.60 (have to single feed because of the Tikka Mag length).

Shot today and not any better results: First set of 3 POA was 2. 1st projectile off target high. ES for group was 7. 2nd group of 3 was at 5, 1&2 were right next to each other, 3 was low. ES 7. 3d group of 3 at 4. ES 20.

So as you can tell, not even close.

My next plan is to load up 3each @ 77.0, 76.0. 75.5 and see if there is better grouping. If they don't work, I may try another powder. There are just so many variables, and my experience level on this is such that I don't have "fallback" "these are things that seem to always work well together (or vice versa, they seldom work together). Any input in appreciated.