Broadhead

FNG

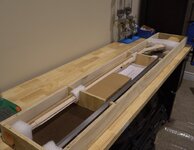

I just received a Kibler Woodsrunner kit in .54 caliber. Everything appears to be top notch quality and very well packaged. Ordered standard maple stock and am impressed with the curl and grain throughout. I've watched all of Jim's videos online and have taken detailed notes throughout. I ordered iron nitrate for the wood stain but have not decided on wood finish or metal finishing solutions. Does anyone have additional tips or tricks they've used while putting their kit together, things to bear in mind, or wood and metal finishing recommendations?